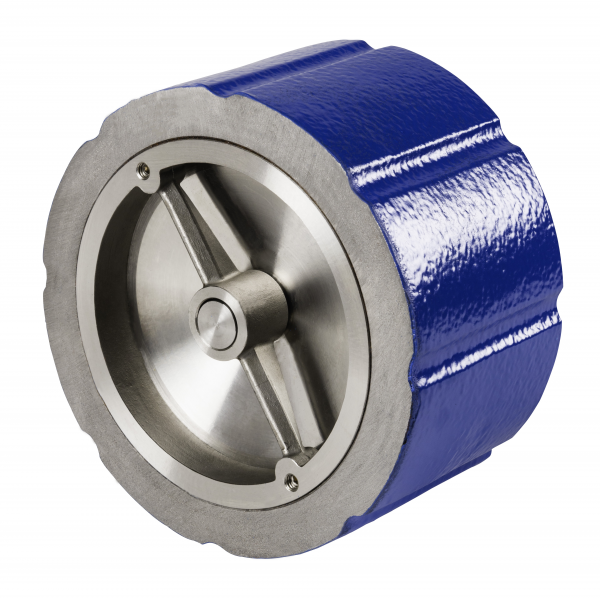

Silent Wafer Check Valve

Series 580

Product Advantages

- Operates Horizontally or Vertically

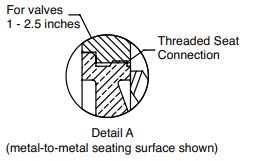

- Watertight Metal-to-Metal Seating

- Field Replaceable Parts

- Factory Mutual Approved – 4 through 10-inches

- Optional Resilient Seat

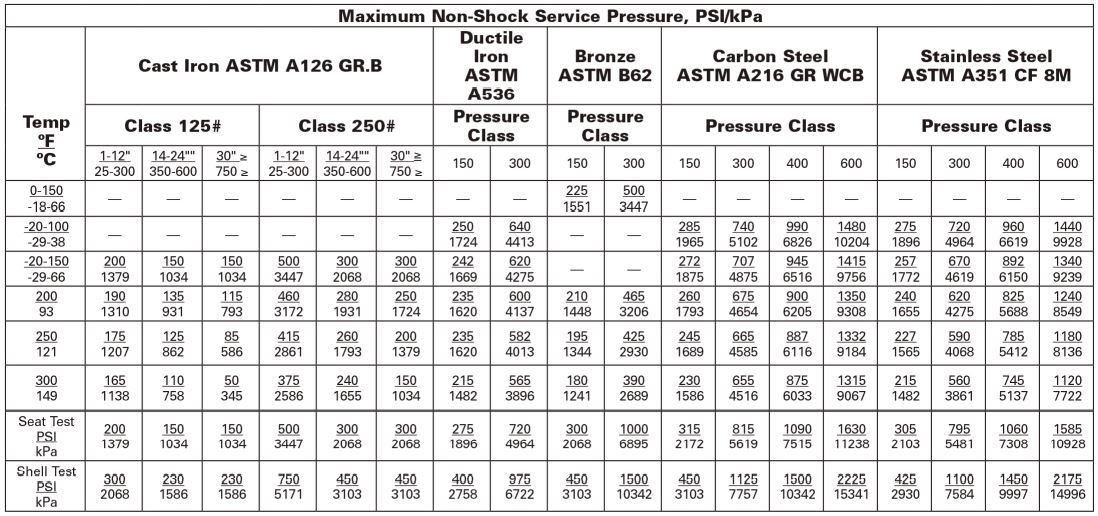

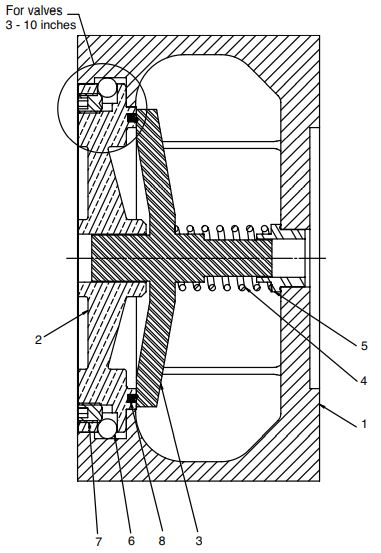

The Cla-Val Series 580 Silent Wafer Check Valve has a spring-loaded poppet that allows the valve to close before flow reversal occurs, resulting in a silent, non-slam closure. It is a truly silent check valve. For ease of installation, the valve can be installed in vertical or horizontal positions with flow up or flow down. The short lay length of the valve allows for a spacesaving design. Silent Wafer Check Valves are available in sizes 1” to 10”, with either a 125/150# or 250/300# pressure

class rating.

Constructed of an epoxy coated ductile iron body with stainless steel trim, the Cla-Val Silent Wafer Check Valve offers watertight shutoff with metal-to-metal seating. For special applications, Buna-N® resilient seats are available as options. All materials conform to ASTM specifications, ensuring long lasting reliable performance. As a confirmation of Cla-Val’s commitment to quality, all Series 580 125/250# class valves are Factory Mutual approved except those supplied with Buna-N® resilient seats.

Approvals & Certifications

- 125/150 Class Valves 4 – 10-inches – FM Approved

- 125/150 & 250/300 Class Valves 1 – 10-inches meet Federal Mandate for Lead Content Limits

Pressure Ratings

- 125/150 (Rated to 250 psi)

- 250/300 (Rated to 400 psi)

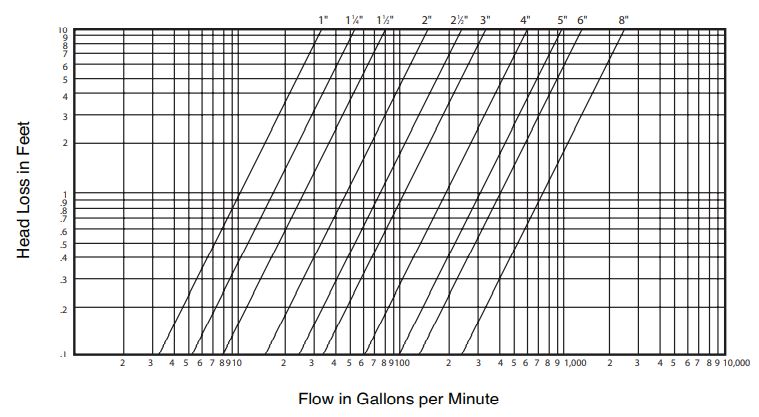

Head Loss Characteristics for 580 Series

Wafer Style Silent Check Valves

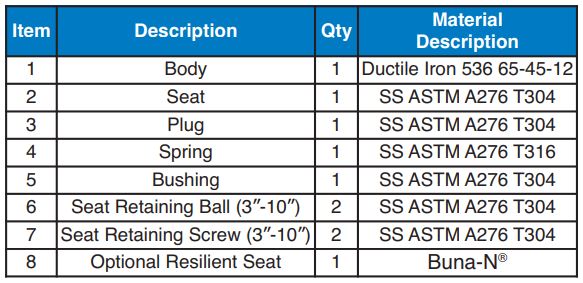

Materials

Valve Body:

Ductile Iron – ASTM 536 65-45-12

Disc & Seat:

304 Stainless Steel –

SS ASTM A276 T304

Spring:

316 Stainless Steel; Stone

Tumbled and Stress Relieved – SS

ASTM A276 T16

Note:

Standard offering is two-part epoxy

coating interior and exterior

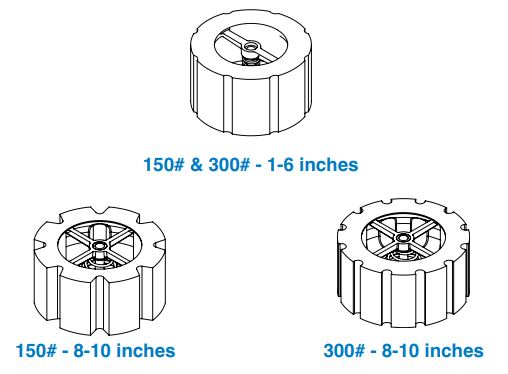

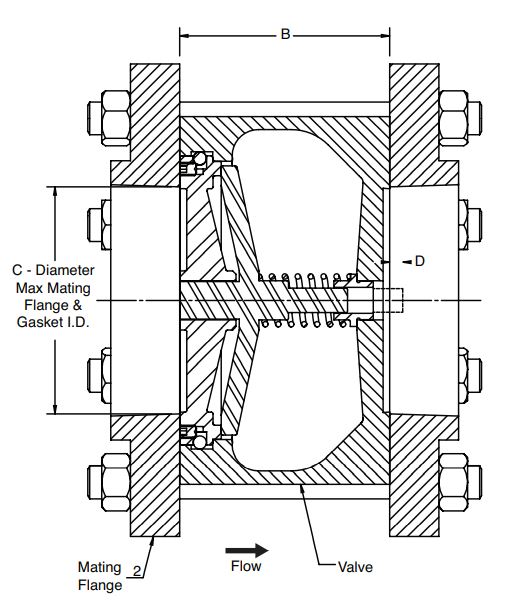

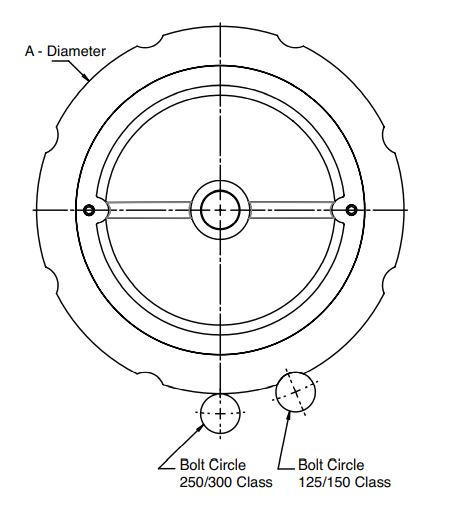

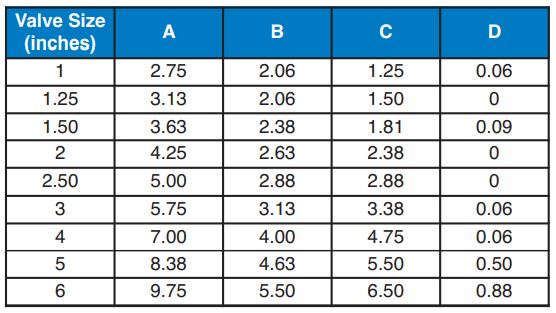

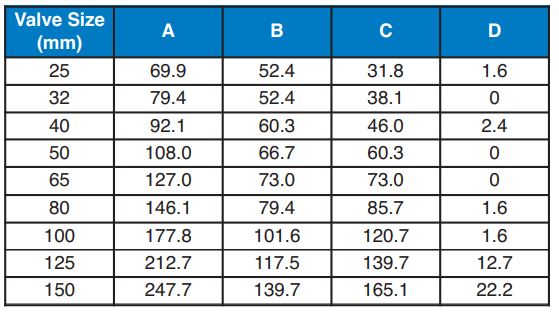

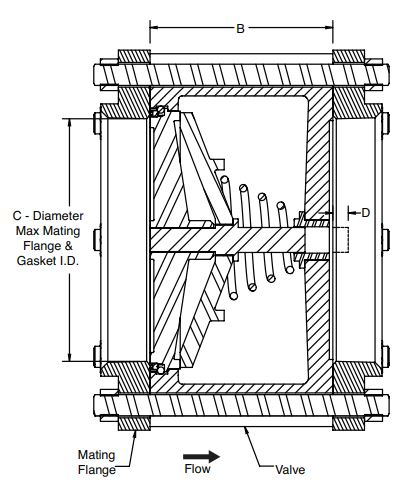

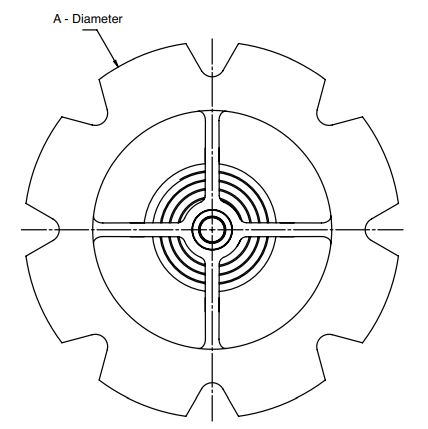

125/150 & 250/300 Class Silent Wafer Check Valve: 1 thru 6-inches

Note: Dimensions are the same for both 125/150 and 250/300 Class Valves.

Specifications

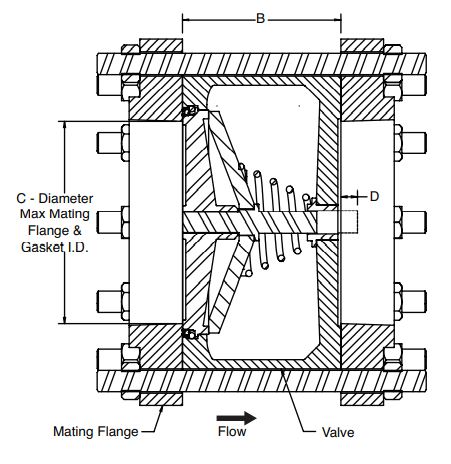

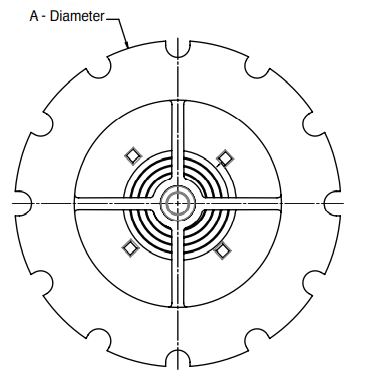

The silent wafer check valve shall consist of a heavy ductile iron body, stainless steel seat, disc, and steel spring. The valve disc shall be center guided at both ends with an integral shaft and shall be spring loaded for silent operation. The spring shall be helical or conical and stone tumbled to achieve a micro-finish to resist mineral deposits. For ease of maintenance, the seat and disc shall be replaceable in the field.

Check valve shall be capable of silent operation when installed in vertical or horizontal positions with either flow up or flow down. The flow area through the body shall be equal to or greater than the cross-section area of the equivalent pipe size.

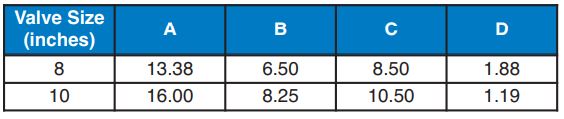

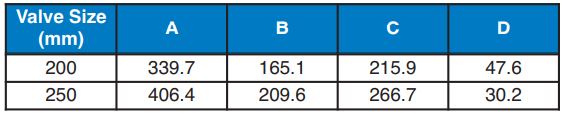

125/150Class Silent Wafer Check Valve: 8 & 10-inches

250/300 Class Silent Wafer Check Valve: 8 & 10-inches

Note: Dimensions are the same for both 125/150 and 250/300 Class Valves

580 Series Silent Wafer Check Valve Technical Data

Typical Applications

- Fire Pump Applications

- Vertical Turbine Pumps

- Booster Pump Stations in High Rise Buildings

- House Pump Application

Cla-Val 580 Series Silent Wafer Check Valves are used anywhere a quick, quiet closure is desired and in the majority of pump applications, including the following;