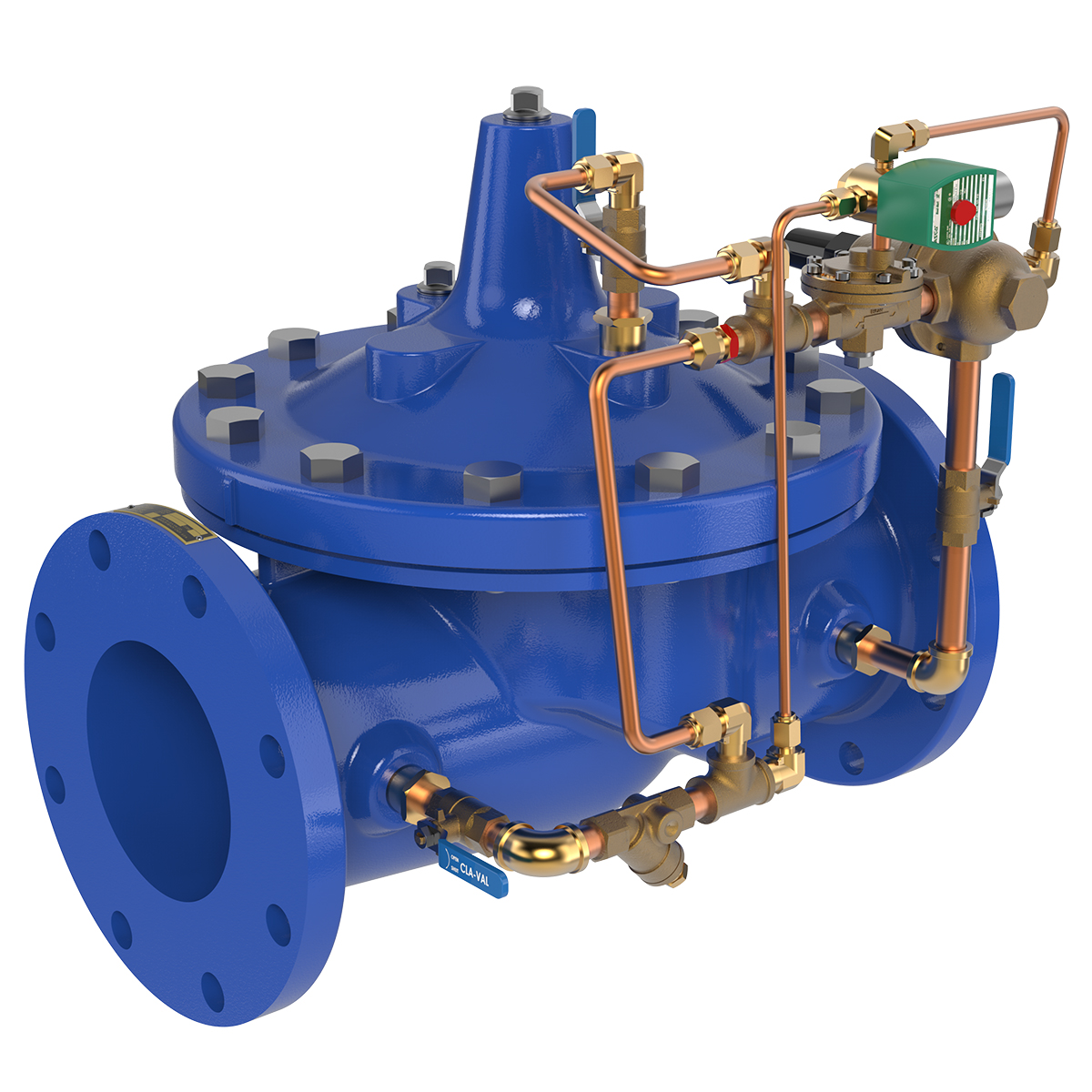

Pressure Reducing & Solenoid Shut-Off Valve

Product Advantages

- Accurate Pressure Control

- Wide Adjustment Ranges

- Optional Check Feature Available

- Quick Acting Solenoid Shut-Off

- Easy Installation and Maintenance

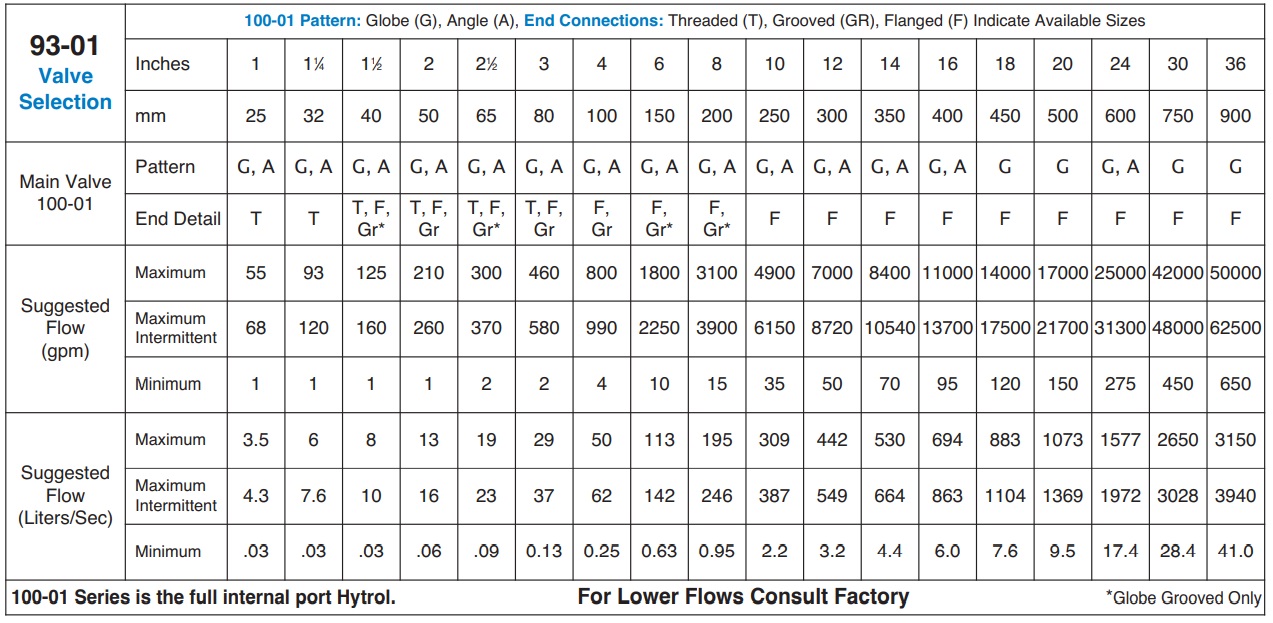

The Cla-Val Model 93-01 Combination Pressure Reducing and Solenoid Shut-Off Valve consists of a Cla-Val Hytrol main valve, a reducing control and a solenoid control connected to the main valve. This valve automatically reduces higher inlet pressure to a steady lower downstream pressure, regardless of changing flow rate and/or varying inlet pressure.

The 93-01 is an accurate, pilot-operated regulator capable of holding downstream pressure to a pre-determined delivery pressure. When downstream pressure exceeds the pressure setting of the control pilot, the pilot valve and main valve close drip-tight. A solenoid control is provided to intercept the operation of the pressure reducing control and close the main valve. This valve is furnished either normally open (deenergized to open), or normally closed (energized to open). Pressure setting adjustment is made with a single adjusting screw.

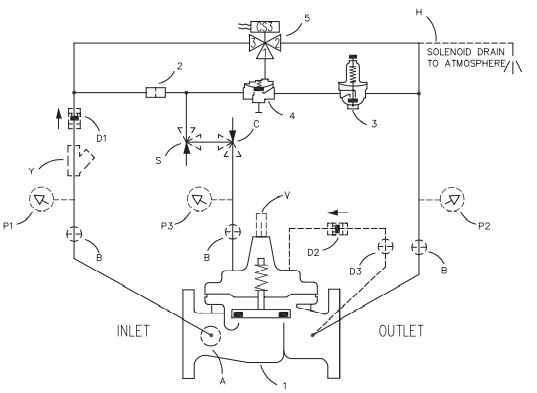

Schematic Diagram

Item Description

1. 100-01 Hytrol Main Valve

2. X58C Restriction Assembly

3. CRD Pressure Reducing Control

4. 100-01 Hytrol (Reverse Flow)

5. CS3 Solenoid Control

Optional Features

Item Description

A. X46A Flow Clean Strainer

B. CK2 Isolation Valve

C. CV Flow Control (Closing)*

D. Check Valves with Isolation Valve

H. Solenoid Drain To Atmosphere

P. X141 Pressure Gauge

S. CV Speed Control (Opening)

V. X101 Valve Position Indicator

Y. X43 “Y” Strainer

*The closing speed control (optional) on this valve should

always be open at least three (3) turns off its seat.

Typical Applications

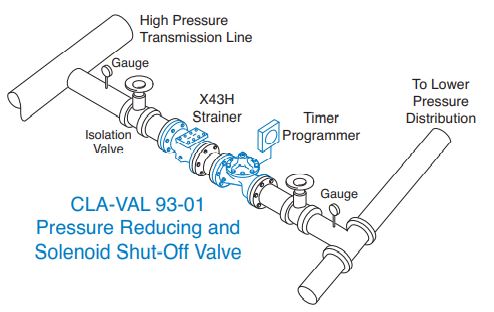

Electronic Control Service

A typical application for this valve is to reduce high transmission line pressures to lower distribution system levels, while opening and closing on command. The solenoid control feature can be activated by an electrical signal from a timer or programmer.

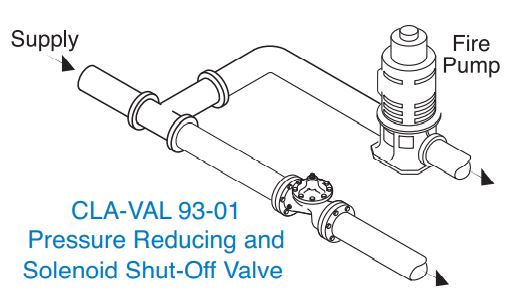

Fire Service

The Model 93-01 can be installed in a distribution line where there is a need to close the valve on the starting of a fire pump. The solenoid control is activated on pump start-up and closes the valve.

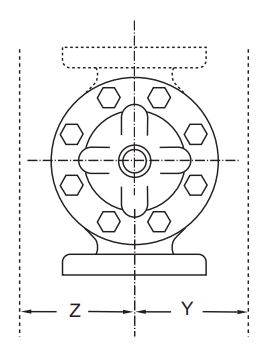

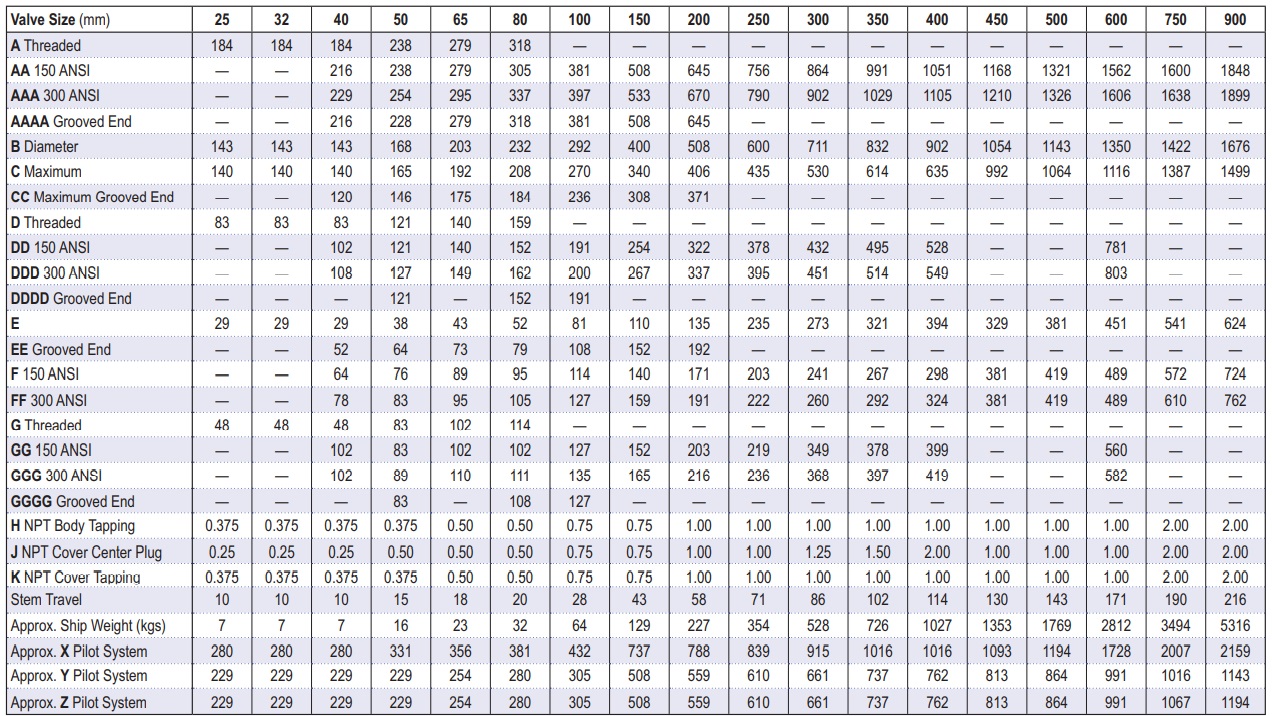

Model 93-01 (Uses 100-01 Hytrol Main Valve)

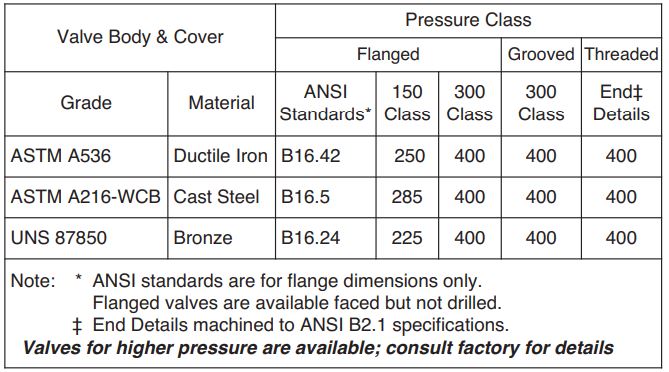

Pressure Ratings (Recommended Maximum Pressure – psi)

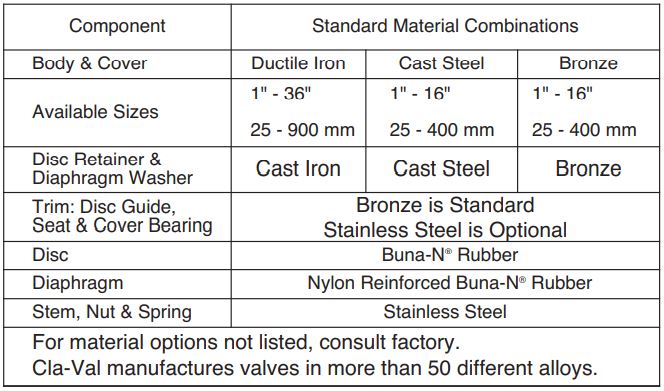

Materials

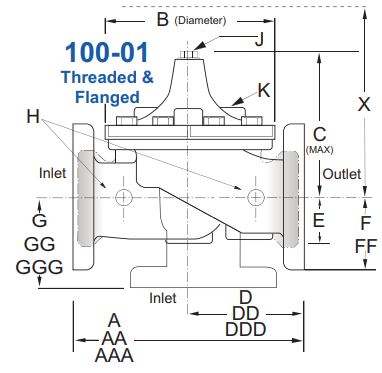

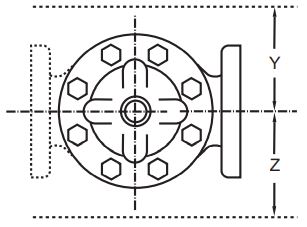

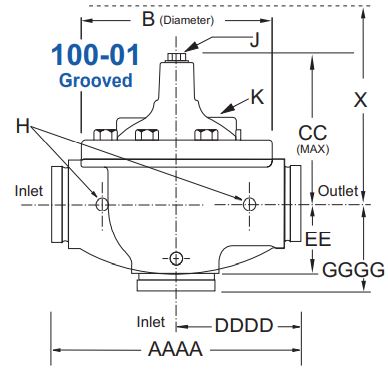

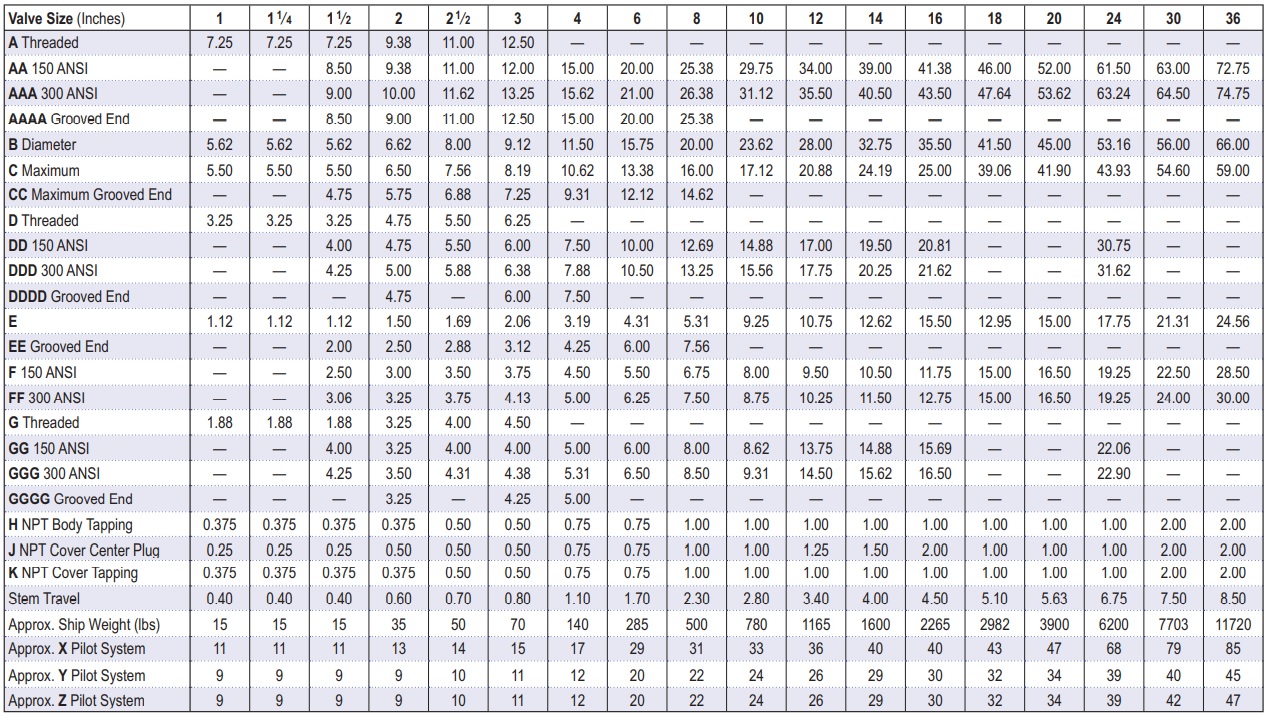

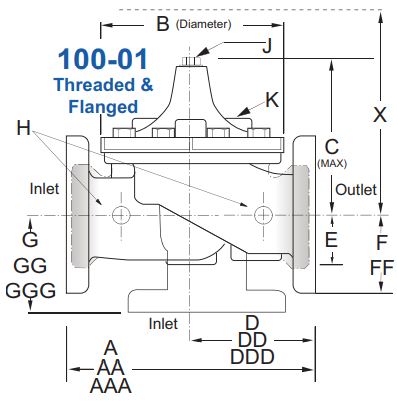

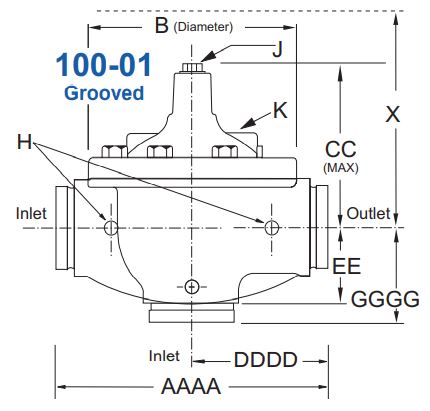

Model 93-01 Dimensions (In Inches)

Model 93-01 Metric Dimensions (Uses 100-01 Hytrol Main Valve)

Valve Options

X141 Pressure

Gauge

X101AR Valve

Position Indicator

with Air Release

X101

Valve Position

Indicator

X144 e-FlowMeter

X43H

Strainer

X43H

Strainer

Stainless

Steel Pilot

Model 93-01 Dimensions (In mm)

Pilot System Specifications

Adjustment Ranges

2 to 30 psi

15 to 75 psi

20 to 105 psi

30 to 300 psi*

*Supplied unless otherwise specified

Other ranges available, please consult factory

Temperature Range

Water: to 180°F

Fluids

Air, water, light oils

Materials

Standard Pilot System Materials

Pilot Control: Low Lead Bronze

Trim: Stainless Steel Type 303

Rubber: Buna-N® Synthetic Rubber

Optional Pilot System Materials

Pilot Systems are available with optional

Aluminum, Stainless Steel, Monel or

Cast Steel materials.

Note: Available with remote sensing control.

Solenoid Control

Body:

Brass ASTM B283

Enclosure:

NEMA Type 1,2,3,3S,4,4X general purpose

watertight*

NEMA Type 6,6P,7,9 Watertight Explosion

Proof available.

Voltages:

110, 220 -50Hz AC

24, 120, 240, 480 – 60Hz AC

6, 12, 24, 120, 240 – DC

Others available at additional cost

Max. operating pressure differential:

200 psi*

Coil:

Insulation molded Class F

Watts AC 6

AC Volt Amps Inrush 30

AC Volt Amps Holding 16

Watts DC 10.6

Manual operator available at additional

cost.

*Supplied unless otherwise specified

Note: Flowing Pressure Differential: 5 psi minimum

When Ordering, Specify:

1. Catalog No. 93-01

2. Valve Size

3. Pattern – Globe or Angle

4. Pressure Class

5. Threaded, Flanged or Grooved

6. Trim Material

7. Energized or de-energized to open

Main Valve

8. Solenoid Enclosure, Voltage &

Hertz, Coil Insulation, and Max.

Operating Pressure Differential

9. Desired Options

10. When Vertically Installed

11. Adjustment Range