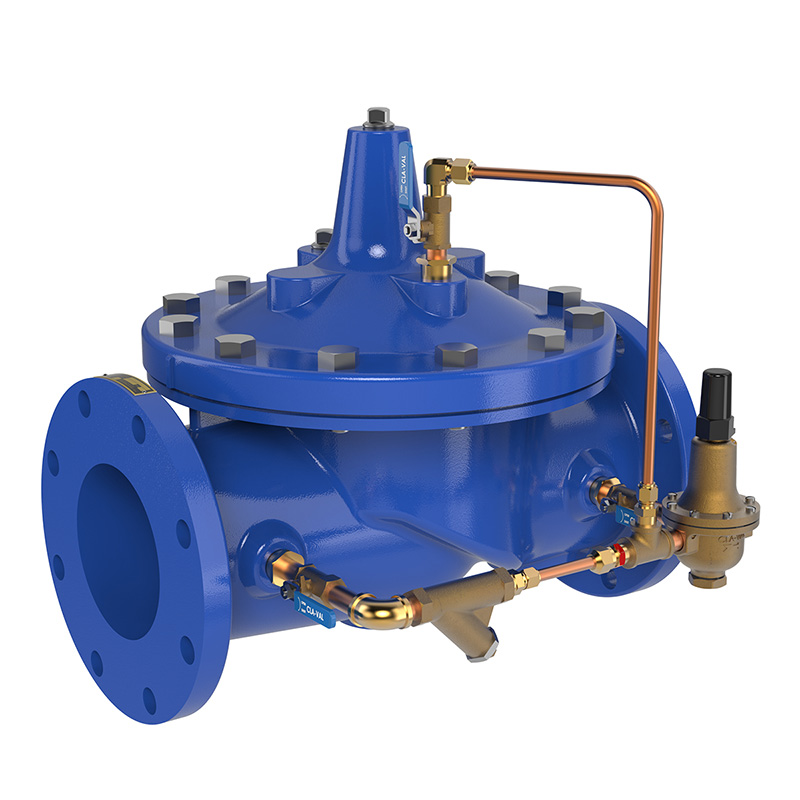

Pressure Reducing Valve

- Sensitive and Accurate Pressure Control

- Easy Adjustment and Maintenance

- Optional Check Feature

- Fully Supported Frictionless Diaphragm

- Meets National Lead Reduction Mandate

The Cla-Val Model 90-01 Pressure Reducing Valve automatically reduces a higher inlet pressure to a steady lower downstream pressure, regardless of changing flow rate and/or varying inlet pressure. This valve is an accurate, pilot-operated regulator capable of holding downstream pressure to a pre-determined limit. When downstream pressure exceeds the pressure setting of the control pilot, the main valve and pilot valve close drip-tight. If a check feature is added, and a pressure reversal occurs, the downstream pressure is admitted into the main valve cover chamber, closing the valve to prevent return flow.

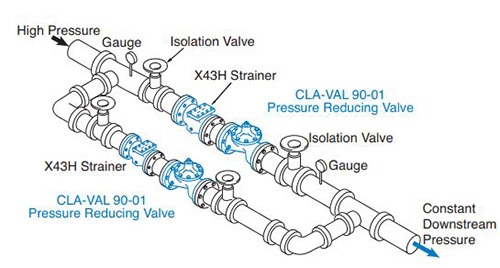

Typical Applications

Typical applications include pressure reducing valve station

using Model 90-01 and Model 90-01 in parallel to handle wide

range of flow rates. Larger Model 90-01 valve meets

requirements of peak loads and smaller Model 90-01 handles

low flows. A downstream pressure relief valve is also

recommended for this type of application.

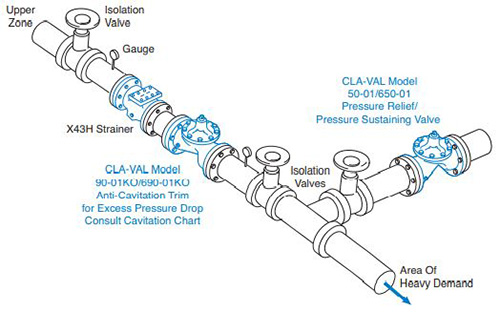

Cla-Val Model 90-01KO Pressure Reducing Valve with AntiCavitation Trim provides for optimum downstream pressure control while reducing noise and eliminating damage associated with cavitation. See Cavitation Guide to determine if the valve is a candidate for the KO Anti-Cavitation Trim. A downstream pressure relief valve is recommended for this type of application.

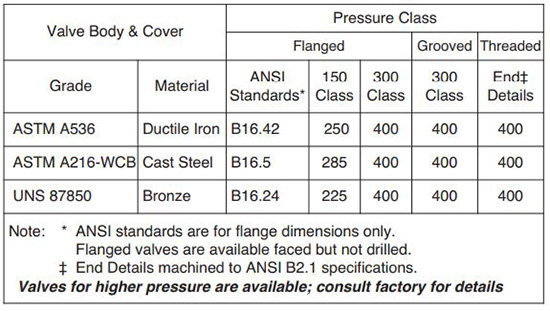

Pressure Ratings

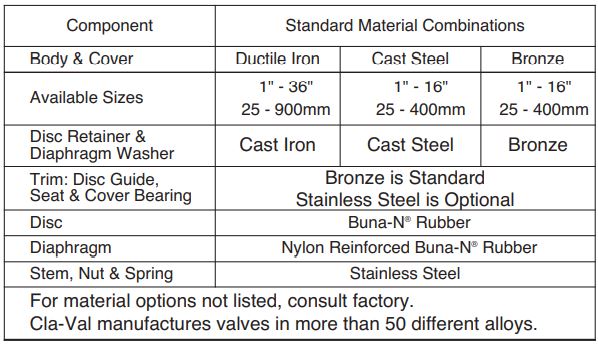

Materials

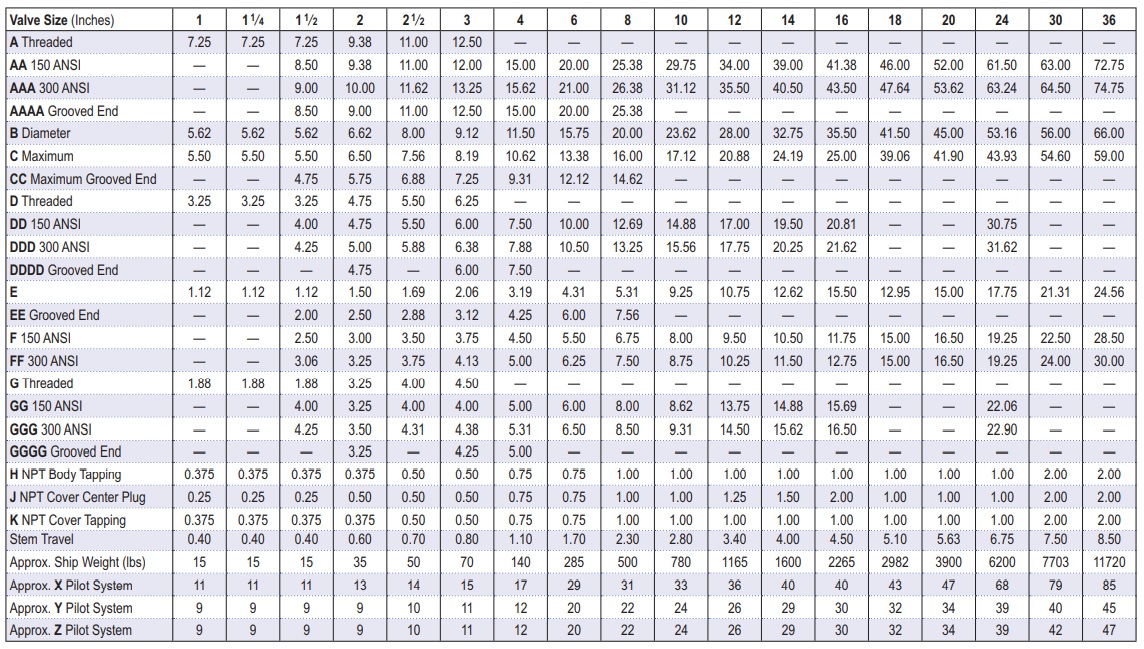

Model 90-01 Dimensions (In Inches)

For sizes 18 through 36-inches, use 90-66 E-Sheet

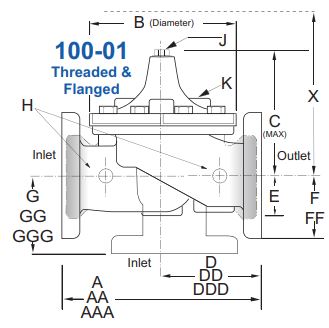

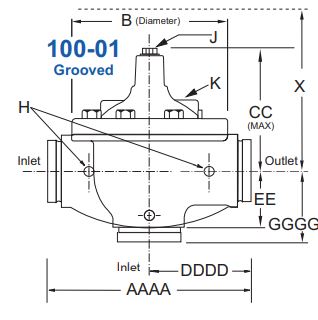

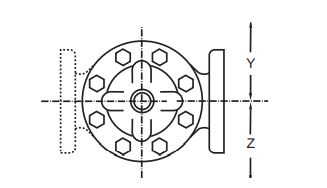

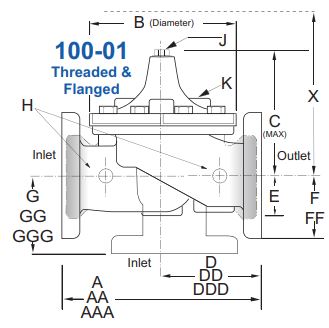

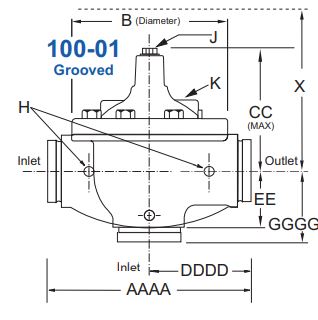

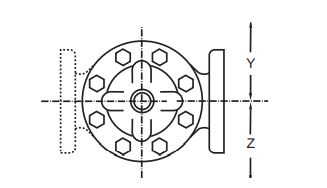

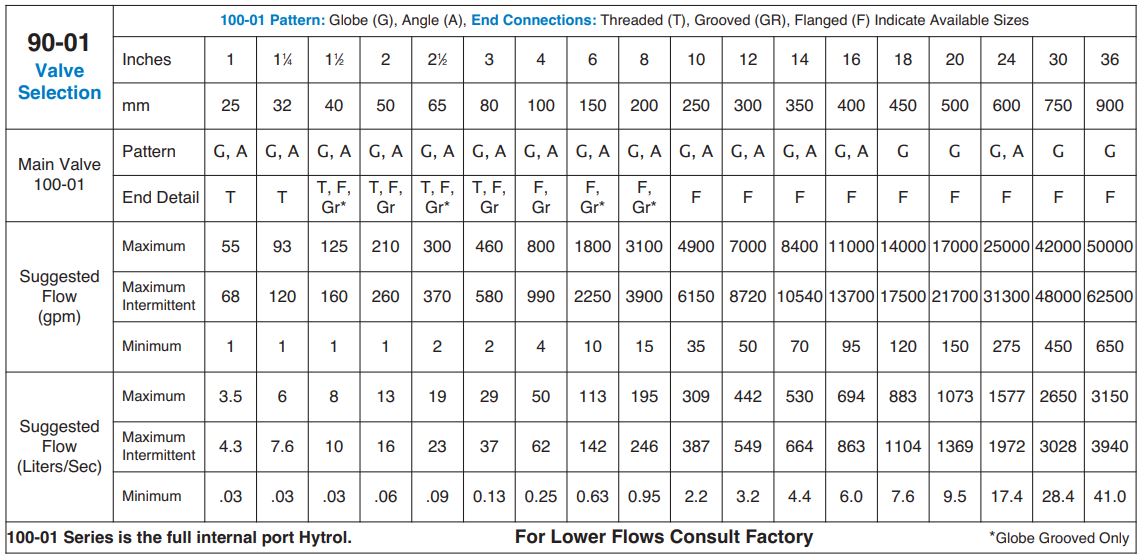

Model 100-01 Full

Port Hytrol Main Valve

Notes:

- For sizes 18 through 36-inches / 450 mm though 900 mm, use 90-66 E-Sheet

- Many factors should be considered in sizing pressure reducing valves including inlet pressure, outlet pressure and flow rates.

- For sizing questions or cavitation analysis, consult Cla-Val with system details.

Pilot System Specifications

Adjustment Ranges

2 to 30 psi

15 to 75 psi

20 to 105 psi

30 to 300 psi*

150 to 600 psi (CRD-18)

*Supplied unless

otherwise specified

Temperature Range

Water: to 180°F

Materials

Standard Pilot System Materials

Pilot Control: Low Lead Bronze

Trim: Stainless Steel Type 303

Rubber: Buna-N® Synthetic Rubber

Optional Pilot System Materials

Pilot Systems are available with optional

Stainless Steel or Monel materials.

Note: Available with remote sensing control.

Main Valve Options

EPDM Rubber Parts

Optional diaphragm, disc and o-ring fabricated with EPDM synthetic rubber

Viton® Rubber Parts – suffix KB

Optional diaphragm, disc and o-ring fabricated with Viton® synthetic rubber

Epoxy Coating – suffix KC

NSF/ANSI 61 Fusion Bonded Epoxy

Dura-Kleen® Stem – suffix KD

Fluted design prevents dissolved minerals build-up on the stem

LFS Trim

Designed to regulate precisely and smoothly at typical flow rates as well as lower than the industry standard of 1 fps, without decreasing the valve’s capacity

Valve Options

X141 Pressure

Gauge

X101

Valve Position

Indicator

X101AR Valve

Position Indicator

with Air Release

X144 e-FlowMeter

Stainless

Steel Pilot

X43H

Strainer