Modulating Float Valve

Product Advantages

- Accurate Level Control

- Completely Automatic Operation

- Simple Operation

- Easy Installation and Maintenance

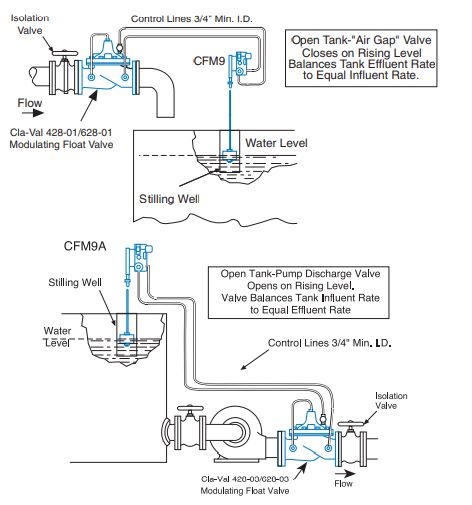

The Cla-Val Model 428-01/628-01 Float Valve modulates to maintain a constant liquid level in a storage tank by compensating for variations in supply or demand. It can be installed to control the flow into or out of the tank by either closing on a rising level or opening on a rising level. This valve is a hydraulically operated, pilot controlled diaphragm valve.

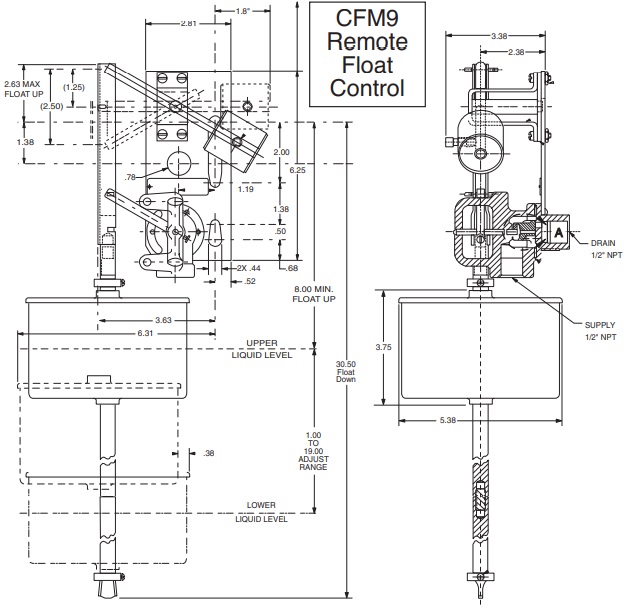

The pilot control system consists of an integral variable orifice in the main valve cover and a remotely mounted float control. A slight change in liquid level moves the float control. This action varies the pressure in the valve cover, causing the main valve to seek a new position. The integral variable orifice automatically regulates the flow into the cover chamber until the valve reaches a position that is in direct relation to the position of the float control.

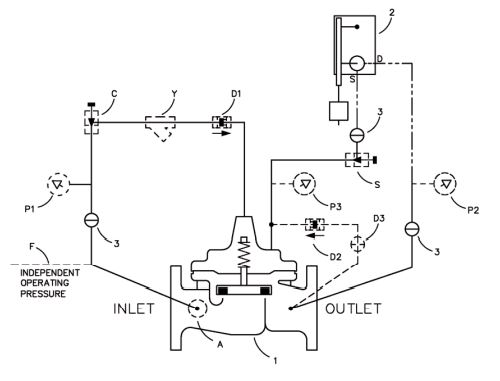

Schematic Diagram

Item Description

1 Hytrol Main Valve

2 CFM-9 Float Control

3 CK2 (Isolation Valve)

Optional Features

Item Description

A X46A Flow Clean Strainer

D Check Valves with Isolation Valve

C CV Speed Control

F Independent Operating Pressure

P X141 Pressure Gauge

S CV Speed Control

Y X43 “Y” Strainer

Installation Data

The valve may be installed in any position. The remote

float control may be mounted at any convenient location above the liquid level. Float rods are available in lengths from 2′ to 12′ in one-foot increments.

A stilling well (8″ min. diameter) should be provided around the float if the liquid surface is subject to turbulence, ripples or wind.

The float control may be installed at any elevation above the valve providing that the amount of flowing line pressure (in psi) is equal to or greater than the vertical distance in feet between the valve and the float control.

When a separate source of supply pressure (Option F) is used by the pilot control system, that pressure must at all times be constant and equal to or greater than the pressure at the valve inlet.

DO NOT USE FOR ON-OFF SERVICE.

Note: We recommend protecting tubing and valve

from freezing temperatures.

Typical Applications

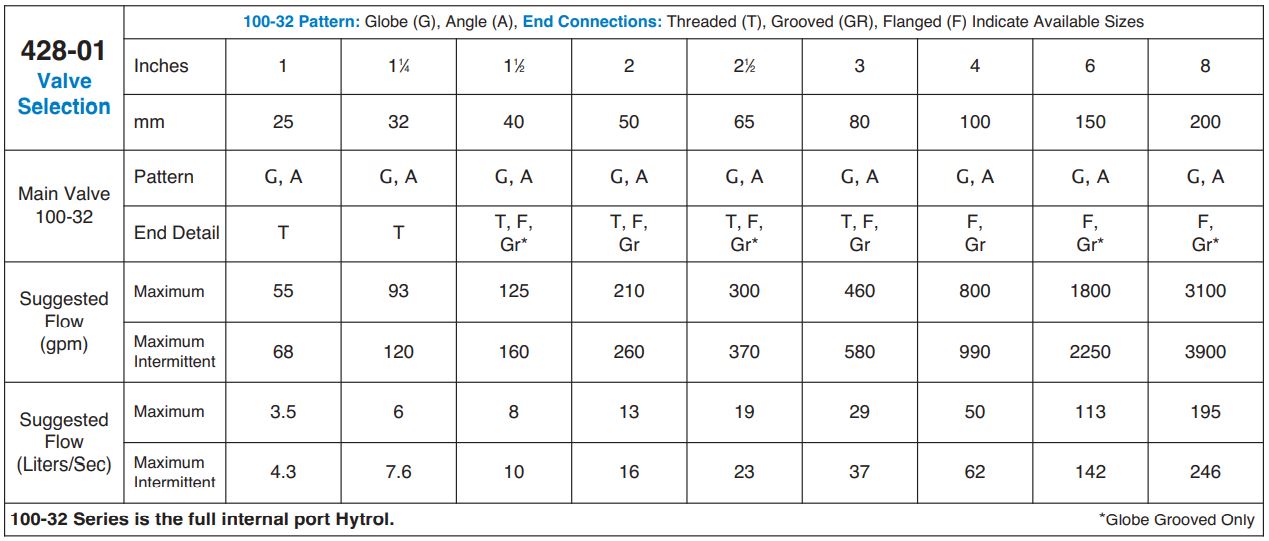

Model 428-01 (Uses Main Valve Model 100-32)

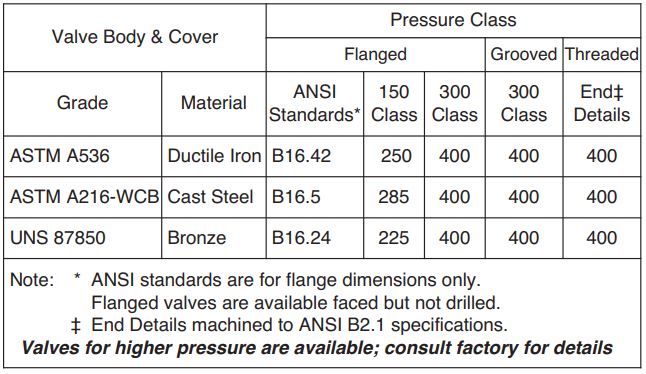

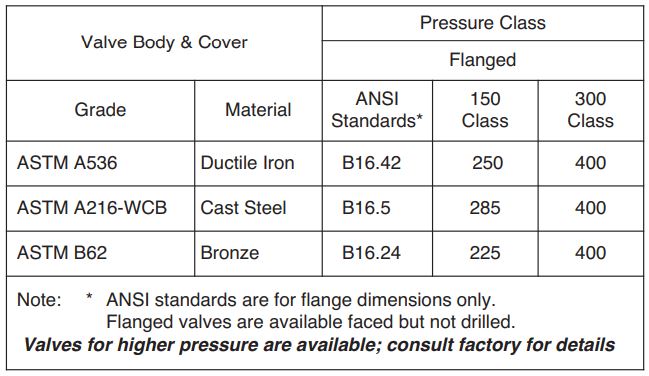

Pressure Ratings (Recommended Maximum Pressure – psi)

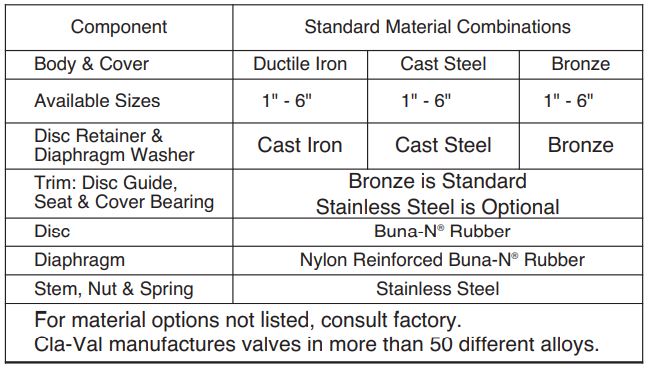

Materials

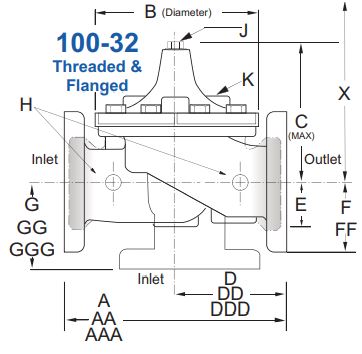

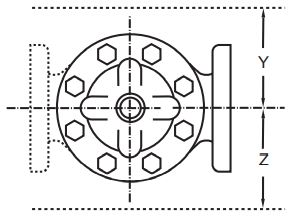

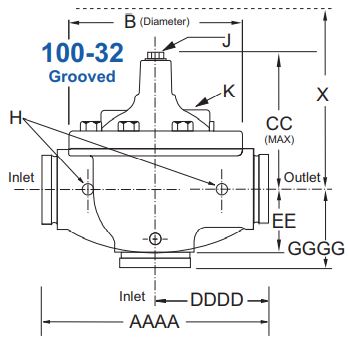

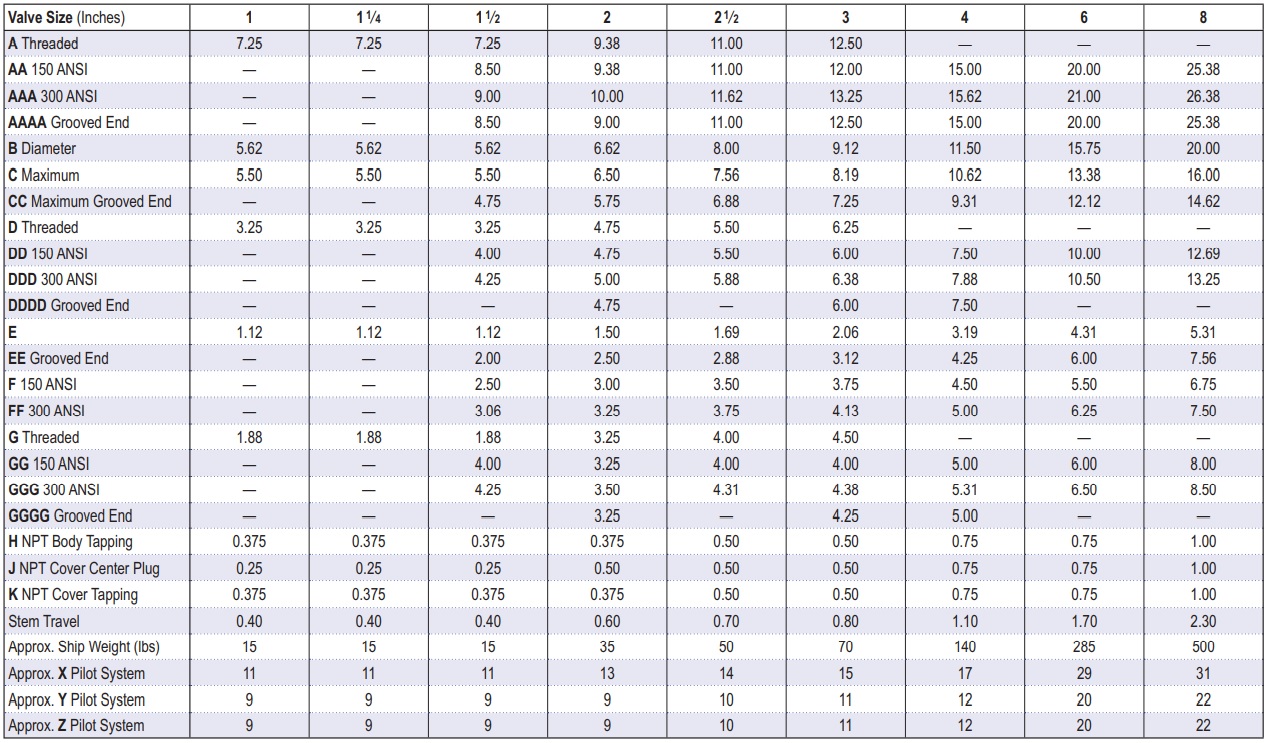

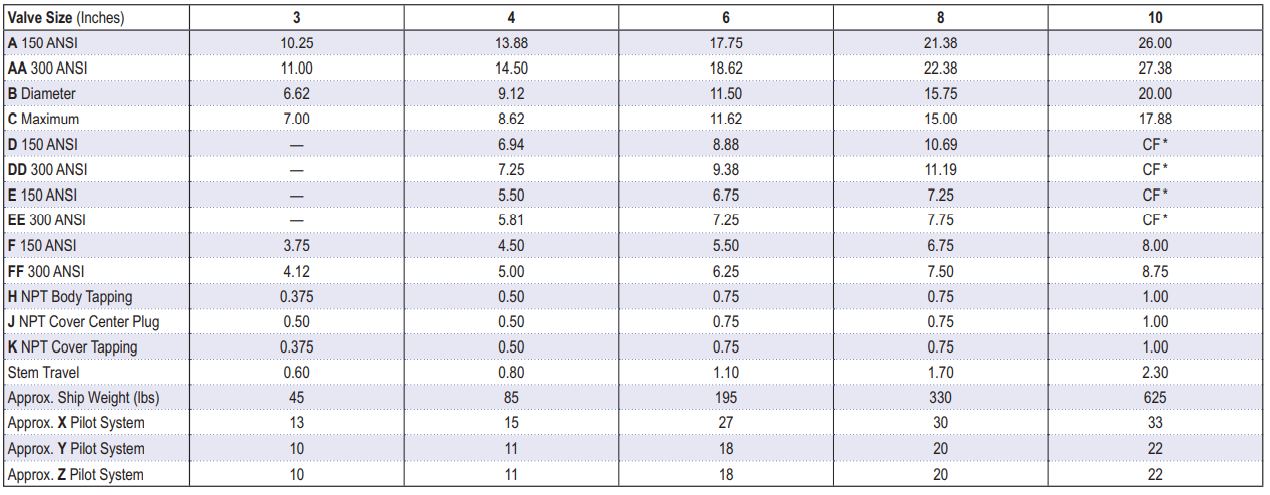

Model 428-01 Dimensions (In Inches)

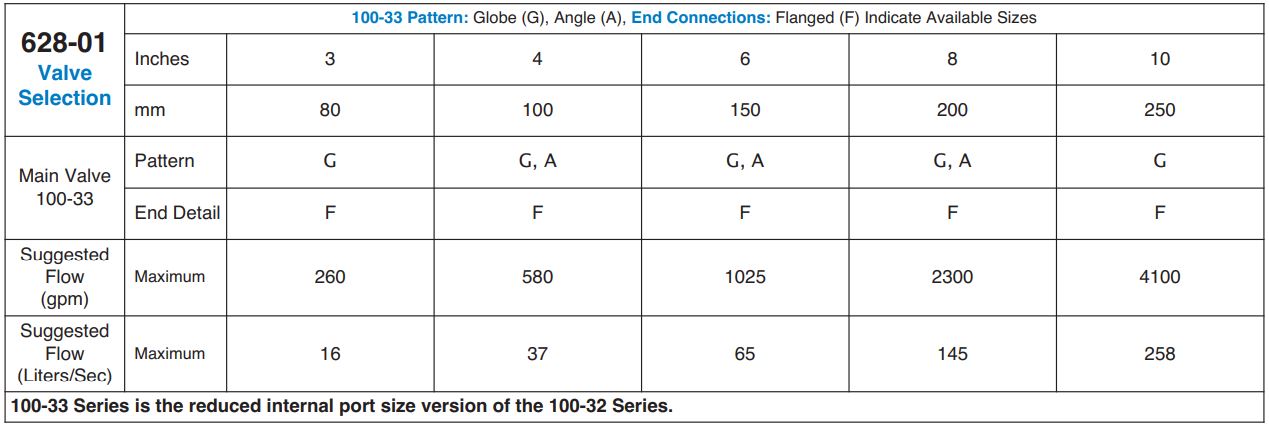

Model 628-01 (Uses Main Valve Model 100-33)

Pressure Ratings (Recommended Maximum Pressure – psi)

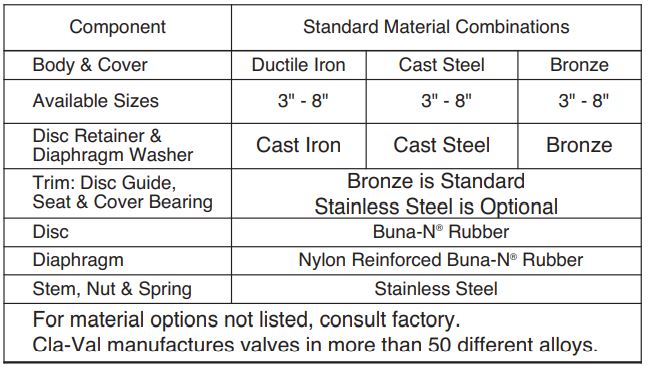

Materials

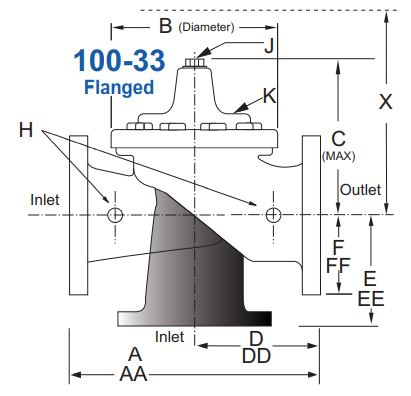

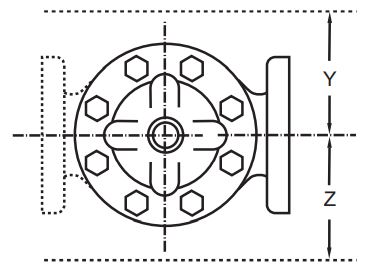

Model 628-01 Dimensions (In Inches)

Pilot SystemSpecifications

Temperature Range

Water: to 180°F

Materials:

In contact with operating fluid:Bronze,

StainlessSteel, Monel, withBuna-N®

Rubber seals.

Float linkage: Brass,

Base plate: EnameledSteel

Float: 304StainlessSteel

Float Rod: Standard – Two 12″ sections of

PVC rod, with 12″ extension increments.

Float Rod: Optional – 24″ stainless steel

rod, with 24″ extension increments.

A larger counterweight is required if float

rod length exceeds 4′. Consult factory for

details.

When Ordering,Please Specify

1. Catalog No. 428-01 or No. 628-01

2. Valve Size

3. Pattern – Globe or Angle

4. Pressure Class

5. Materials Desired

6. Threaded or Flanged

7. Valve Closing or Valve Opening on Rising Water Level

8. Desired Options