Electronic Control Valves

Product Advantages

- Simple Proven Design

- Quality Solenoid Pilot Controls

- Ideal For SCADA Systems

- Multi-Function Capability; Hydraulic Backup

- Security System to Prevent Unauthorized Changes

- Easy to Maintain

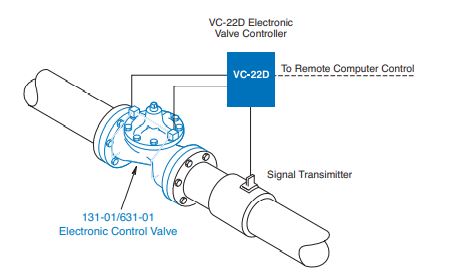

The Cla-Val Series 131 Electronic Control Valves are designed specifically for applications where remote control of the valve is preferred. It is a hydraulically operated, pilot controlled, diaphragm valve. The solenoid pilot controls are actuated by electrical signals from the optional VC-22D Electronic Valve Controller. The solenoid pilots either add or relieve line pressure from the cover chamber of the valve, causing it to open or close as directed by the electronic controller.

Series 131 Electronic Control valves can be configured to perform a wide range of functions, such as; pressure reducing, pressure sustaining, flow control, or level control. The electric controls can also be combined with hydraulic controls to create dual function, or fail-safe capability.

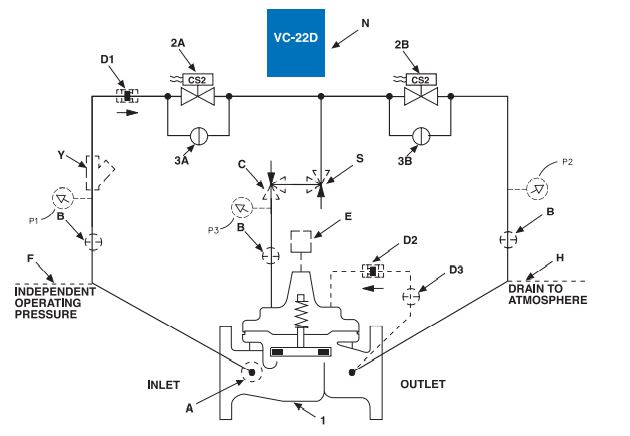

The basic 131-01 Electronic Control Valve (Schematic shown below) includes the main valve and solenoid pilot controls. Optional features include the VC-22D Electronic Valve Controller and the X117 Series Valve Position Transmitter. If the check feature option is added, and a pressure reversal occurs, the downstream pressure is admitted into the cover, closing the valve.

Schematic Diagram

Item Description

1. 100-01 Hytrol Main Valve

2. CS2 Solenoid Control

3. CK2 Solenoid Bypass Valve

Optional Features

Item Description

A. X46A Flow Clean Strainer

B. CK2 Isolation Valve

C. CV Flow Control (Closing)

D. Check Valves With Isolation Valve

E. X117 Series Position Transmitter

F. Independent Operating Pressure

H. Atmospheric Drain

N. Electronic Controller

P. X141 Pressure Gauge

S. CV Flow Control (Opening)

Y. X43 “Y” Strainer

Typical Applications

This data sheet contains typical applications that are modifications to the basic 131-01 Electronic Control Valve shown here. It is typically installed in a pipeline with a VC-22D Series Controller that receives a process variable signal that is compared to a set point and adjusts the main valve’s capacity until the signals match. There are many different variations not shown in this brochure. Contact us with your specific application and we will provide a field proven solution.

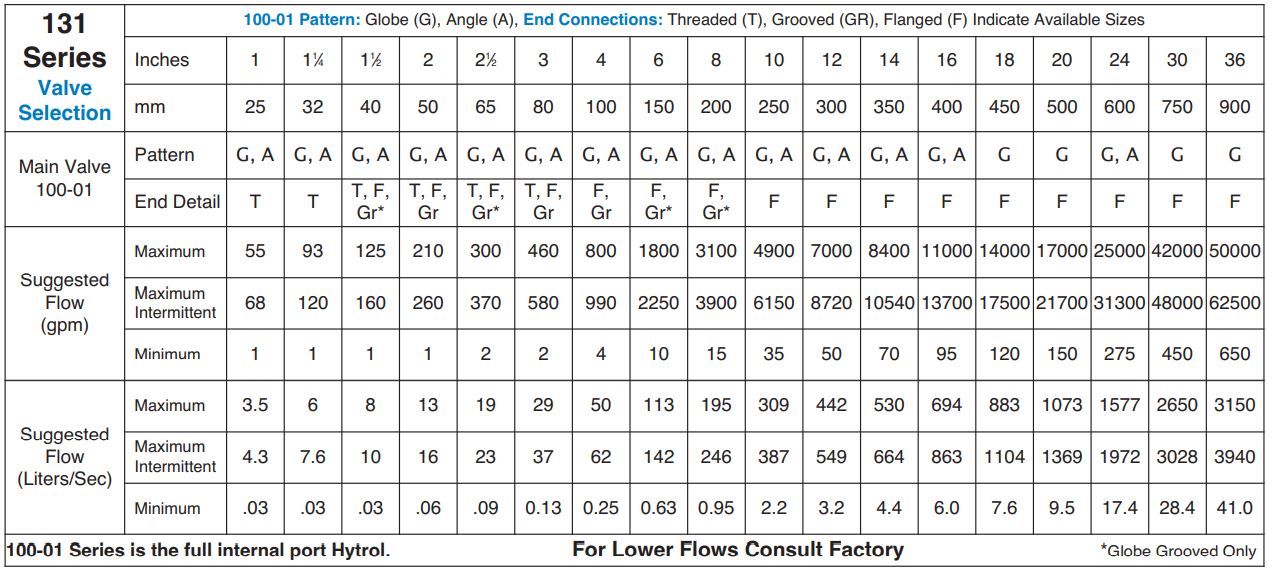

131 Series (Uses 100-01 Hytrol Main Valve)

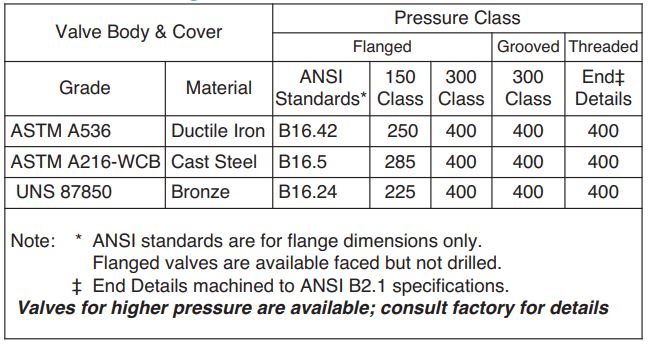

Pressure Ratings (Recommended Maximum Pressure – psi)

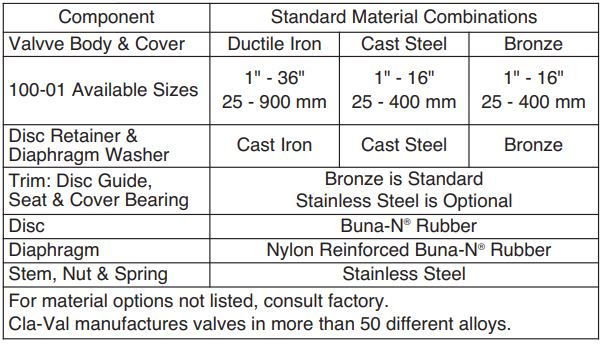

Materials

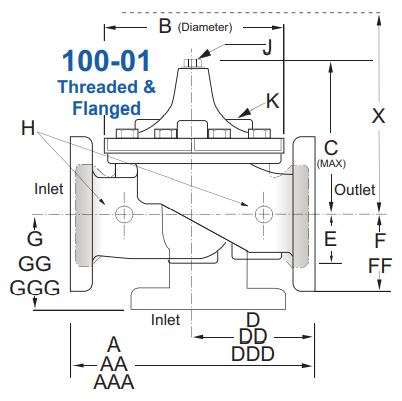

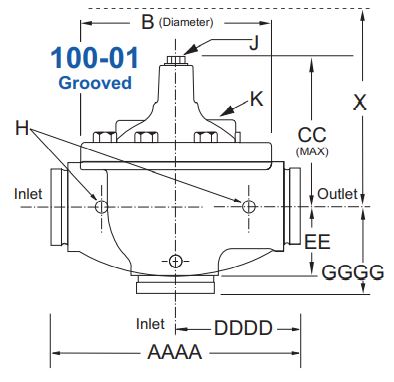

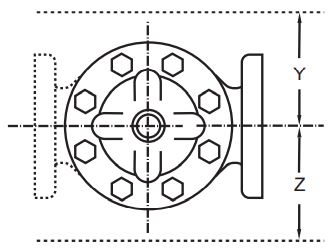

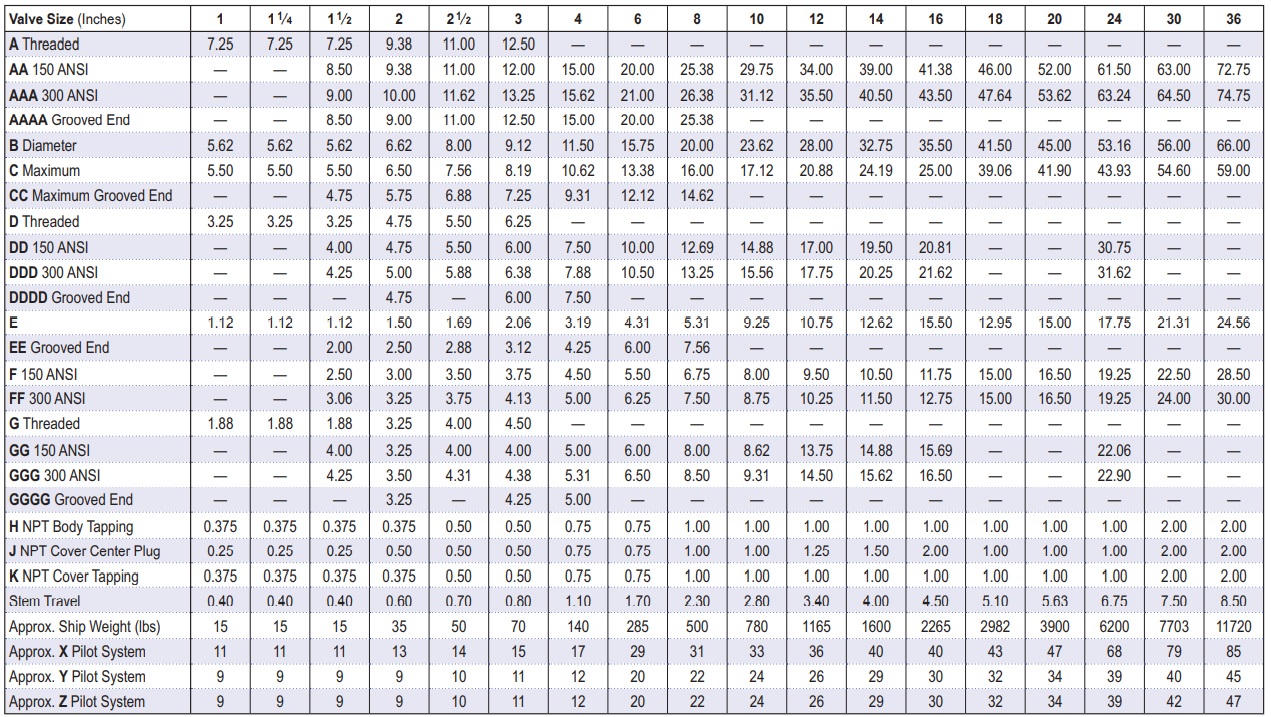

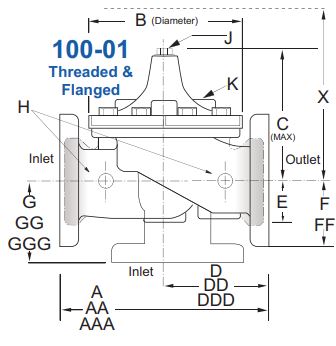

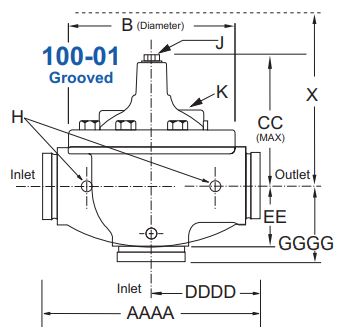

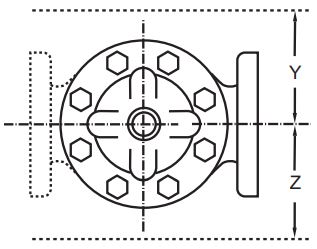

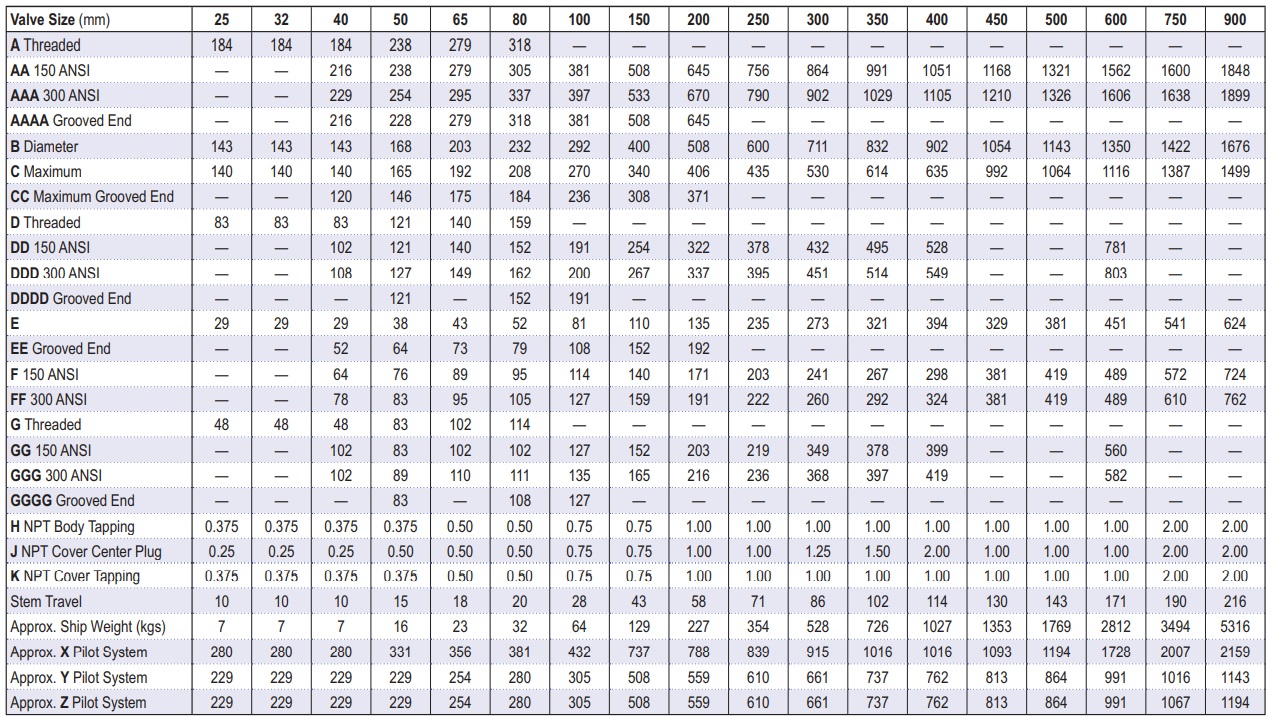

131 Series Dimensions (In Inches)

131 Series Metric Dimensions (Uses 100-01 Hytrol Main Valve)

Model 100-01 Full Port Hytrol Main Valve

for applications requiring a reduced port valve, please refer to the 631 Series Engineering Data Sheet

131 Series (Uses 100-01 Hytrol Main Valve)

131 Series Pilot System Specifications

Temperature Range

Water: to 180°F

Rubber Parts:

Buna-N® Rubber Synthetic

Solenoid Control

Body:

Brass ASTM B283

Enclosure:

NEMA Type 1,2,3,3S,4,4X general purpose

watertight*

NEMA Type 6,6P,7,9 Watertight Explosion-Proof

available.

Voltages:

110, 220, -50Hz Ac

24, 120, 240, 480 – 60Hz AC

6, 12, 24, 120, 240 – DC

Others available at extra cost

Max. operating pressure differential: 200 psi

unless otherwise specified

Coil:

Insulation molded Class F

Watts AC 6

AC Volt Amps Inrush 30

AC Volt Amps Holding 16

Watts DC 10.6

When Ordering, Specify:

1. Catalog No. 131 Series

2. Valve Size

3. Pattern – Globe or Angle

4. Pressure Class

5. Threaded, Flanged or

Grooved

6. Trim Material

7. Adjustment Range

8. Desired Options

9. When Vertically Installed

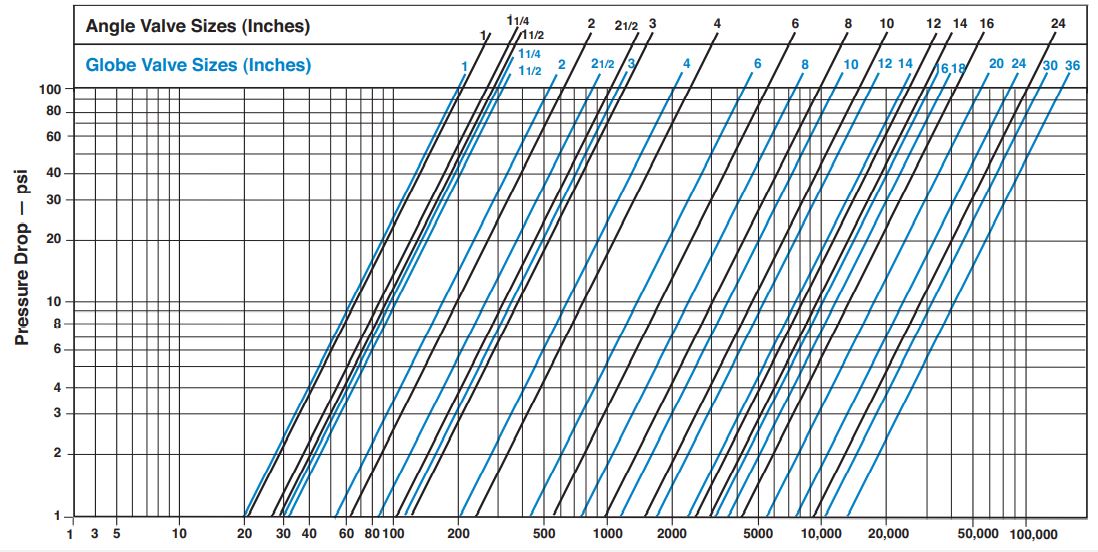

131 Series Flow Data