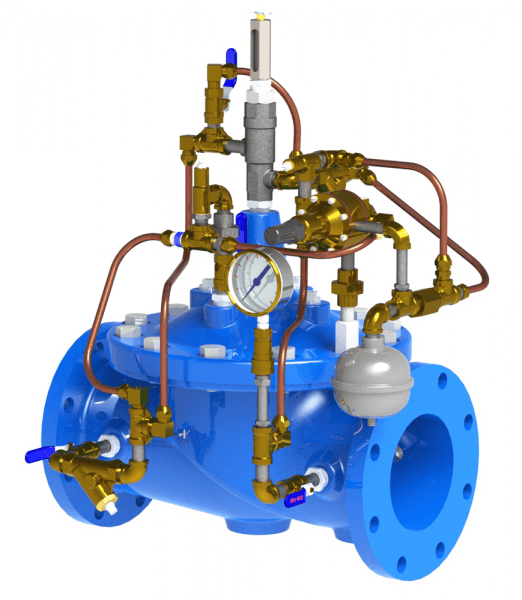

Hydraulic Pressure Management/Water Savings Valve with Dual Setpoints

Product Advantages

- Simple means to achieve measurable water savings

- Helps reduce consumption

- 100% hydraulic control

- Two adjustable downstream set points for high and low pressure

- Smooth transition between set point pressures

- Simple set-up

- Retrofits to existing valve without removal from pipeline

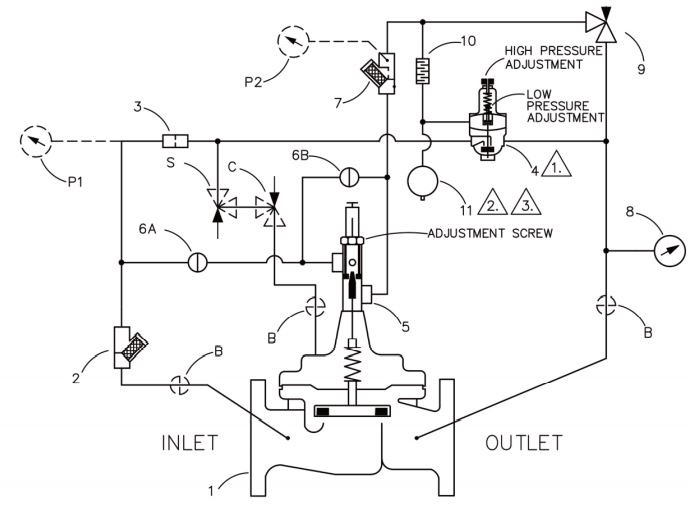

Schematic Diagram

Item Description

1. 100-01 Hytrol Main Valve

2. X43 “Y” Strainer

3. X58C Restriction Assembly

4. CPM-A Pressure Management Control

5. X78-4 Stem Assembly + X101 Valve Position Indicator Assembly

6. CK2 Isolation Valve

7. X44A Strainer Orifice Assembly

8. X141 Gage Assembly

9. CV Speed Control

10. X58E Restriction Assembly

11. Accumulator (Air Charged)

Optional Features

Item Description

B. CK2 Isolation Valve

C. CV Flow Control (Closing)

P. X141 Gage Assembly

S. CV Flow Control (Opening)

Optional Features

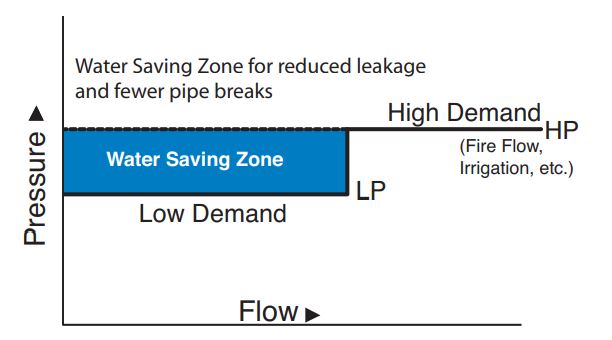

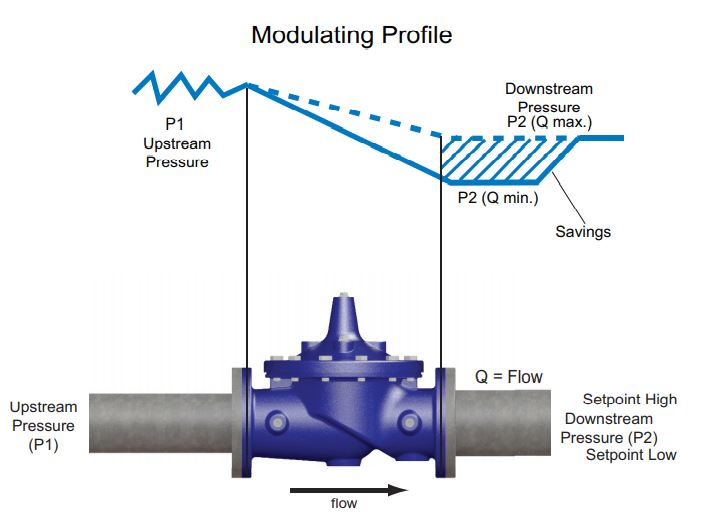

A dual system pressure with reduced system pressure during low demand periods is illustrated in the chart. At low flows, a minimum pressure is maintained and as flow increases to the switch point, delivery pressure increases to the maximum pressure set point for switch. The point between low pressure and high pressure setpoints is adjustable to fine-tune the valve to system requirements. The “water saving zone” below maximum pressure line represents valve effectiveness in reducing water losses and frequency of pipe breaks in a system

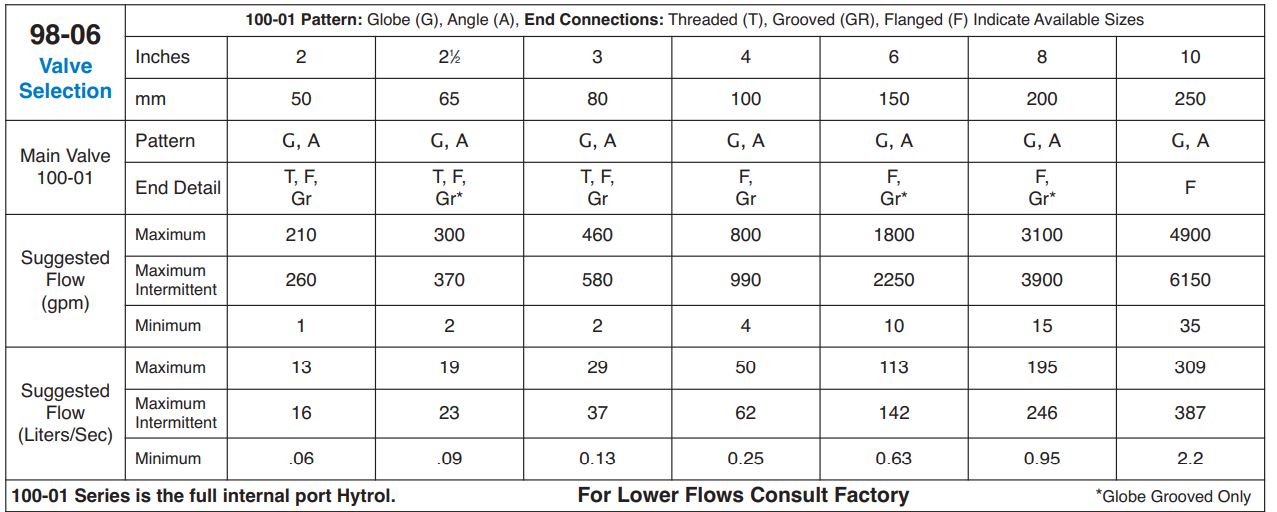

Model 98-06 (Uses 100-01 Hytrol Main Valve)

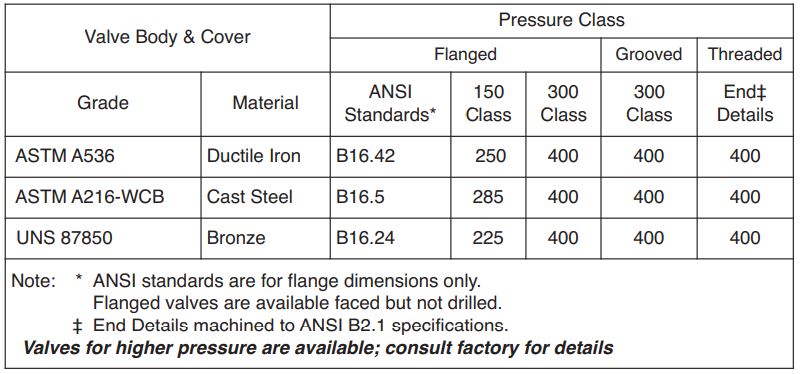

Pressure Ratings (Recommended Maximum Pressure – psi)

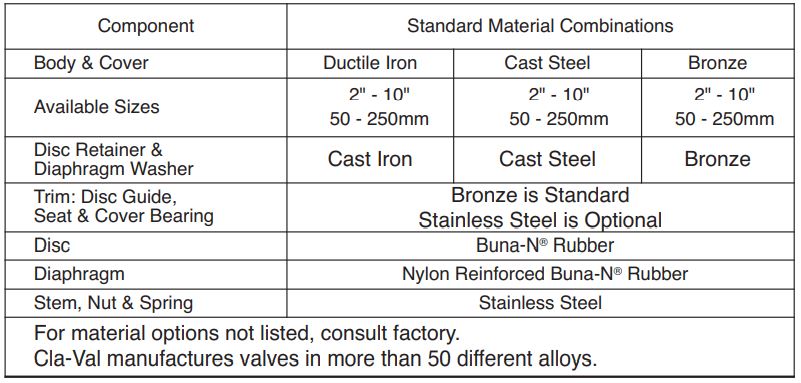

Materials

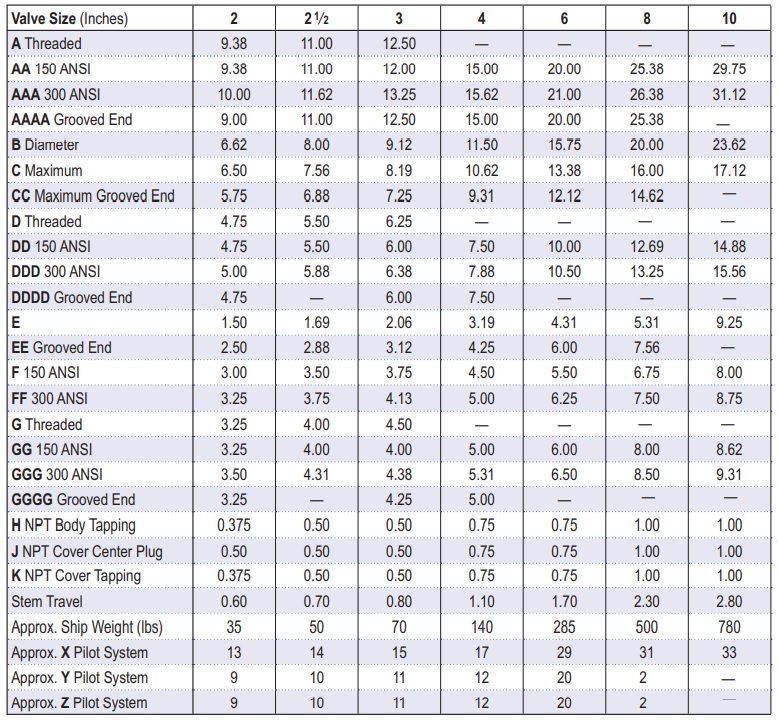

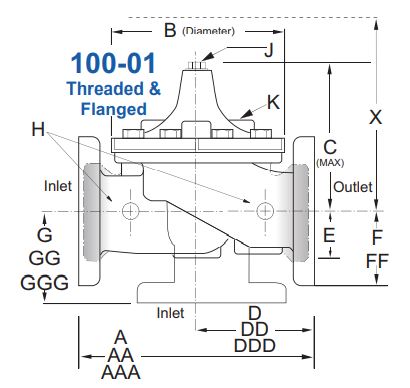

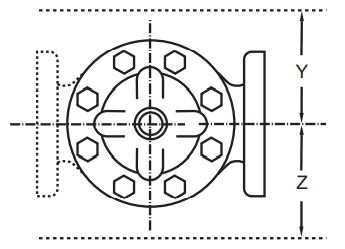

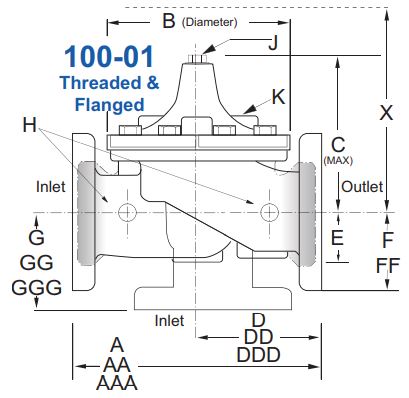

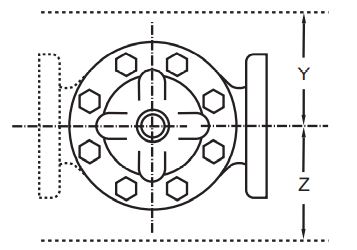

Model 98-06 Dimensions (In Inches)

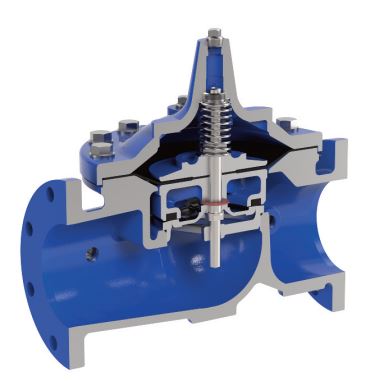

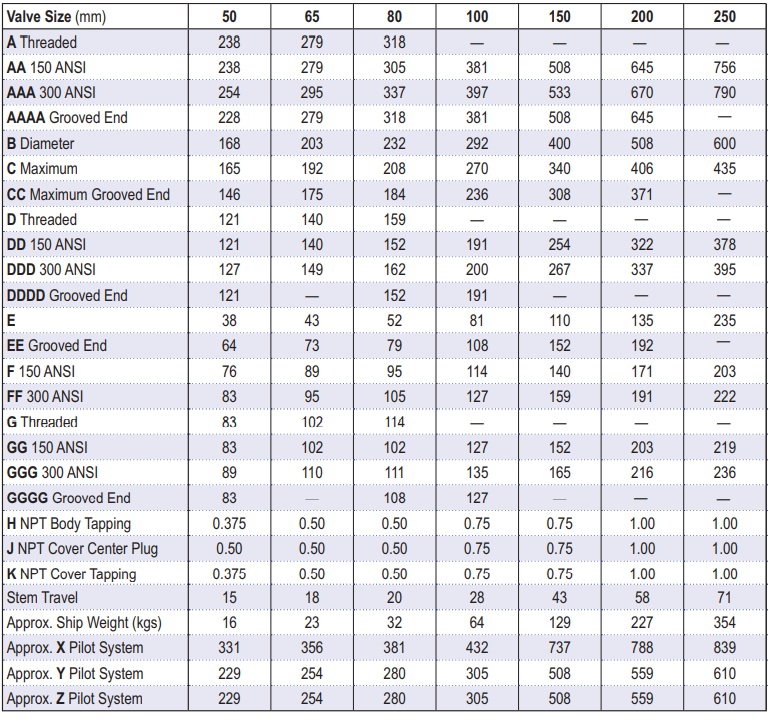

Model 100-01 FullPort Hytrol Main Valve

Model 98-06 Metric Dimensions (Uses 100-01 Hytrol Main Valve)

Dimensions (In mm)

How It Works

The Cla-Val Model 98-06 Water Saving Valve is a pressure reducing valve that uses two downstream set points to achieve optimum system pressure; i.e. the capability delivering only the pressure that is needed to meet current demand.

A high pressure set point is selected for high flow demand and a low pressure set point is selected for low demand. This dual set point arrangement allows for reduction in water consumption as well as unintentional water loss by keeping system piping from being over-pressurized during periods of low demand. It does this without inhibiting adequate pressure during high or fire demand. The design is 100% hydraulic and, in addition, to the dual pressure set points, the transition point at which the pressure changes based on the flow is also adjustable. The patented design of the valve allows for smooth transition from one set point to the other, providing optimum performance and measurable water savings by reducing consumption, minimizing leaks and

lessening the potential for pipe breaks.

Many factors should be considered in sizing pressure reducing valves including inlet pressure, outlet pressure and flow rates. For sizing questions or cavitation analysis, consult Cla-Val with system details.

Not Recommended for Dead-end Service

Pilot System Specifications

Temperature Range

Water: to 180°F

Materials

Standard Pilot System Materials

Pilot Control: Stainles Steel & Low Lead Bronze

Trim: Stainless Steel Type 303

Rubber: Buna-N® Synthetic Rubber

When Ordering, Specify:

1. Catalog No. 98-06 2. Valve Size

3. Pattern – Globe or Angle 4. Pressure Class

5. Threaded or Flanged 6. Trim Material

7. Desired Options 8. When Vertically Installed