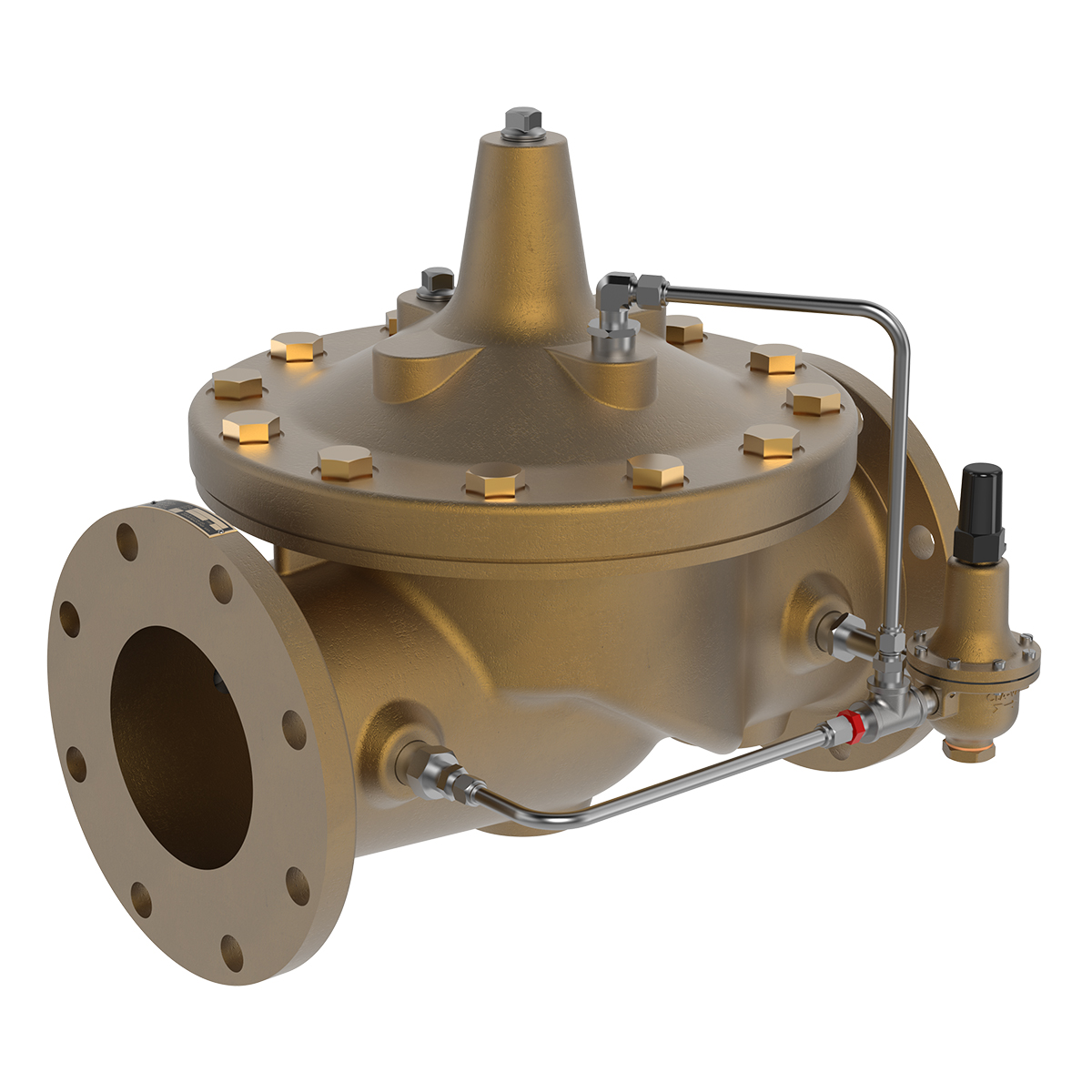

Seawater Service Pressure Reducing Valve

Product Advantages

- Globe or Angle Pattern

- Proven Reliable Design

- Available in Cast Bronze, Iron and Steel

- Accurate Pressure Control

- In Line Service

Cla-Val 90G-42 (globe) and 90A-42 (angle) Pressure Reducing Valves are indispensable in any fire protection system. Our diaphragm actuated design is proven highly reliable and easy to maintain. We offer both a globe or angle pattern with a full range of adjustments. These valves are available in cast bronze, iron or steel and all special alloys.

Ductile iron and cast steel valves are supplied with internal and external epoxy coating of the main valve wetted surfaces.

If UL Listed is required for Model 90-42 Seawater Service use Model 90-21KX when ordering. UL Listed sizes limited to 1 1⁄2 – 8” sizes.

Function

Cla-Val Model 90G-42 (globe) and 90A-42(angle)

Seawater Service Pressure Reducing Valves automatically reduce a higher inlet pressure to a steady lower outlet pressure regardless of changing flowrate and/or varying inlet pressure. The valves pilotcontrol system is very sensitive to slight downstream pressure fluctuations, and will automatically open or close to maintain the desired pressure setting. The downstream pressure can be set over a wide range by turning the adjustment screw on the CRD pilot control. The adjustment screw is protected by a screw-on cover, which can be sealed to discourage tampering.

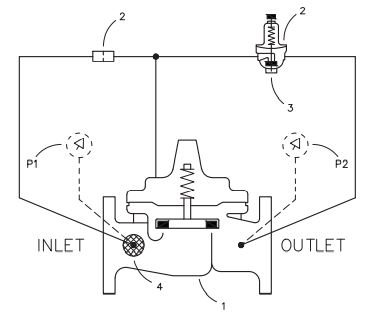

Schematic Diagram

Item Description

1. Model 100S/2100S Hytrol (Globe or Angle)

2. X58C Restriction Tube Fitting

3. CRD Pressure Reducing Control

4. X46A Flow Clean Strainer

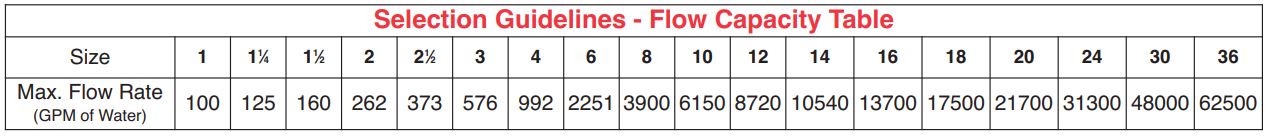

Sizes:

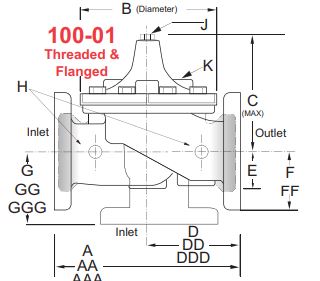

Threaded Ends: 1″ – 3″

Globe Flanged: 2″ – 36″

Angle Flanged: 2″ – 16″

End Details:

Cast Steel ANSI B16.5

Bronze ANSI B16.24

Stainless Steel ANSI B16.5

Ductile Iron ANSI B16.42

Pressure

Ratings:

150 Class 250 psi Max.

300 Class 400 psi Max.

Temperature

Range:

Water 180°F Max.

Materials:

Main valve body & cover

Ductile Iron ASTM A-536*

Cast Steel ASTM A216-WCB*

Naval Bronze ASTM B61

Naval Bronze ASTM B61

Ni. AL. Bronze ASTM B148

Super Duplex SST

Monel QQ-N-281 Class B

Main valve trim:

ASTM B61 Bronze Seat,

Monel Trim

Pilot control system:

Cast Bronze with Monel Trim

Monel, Super Duplex Stainless Steel optional

Stainless Steel 316 Tubing & Fittings

Adjustment

Ranges:

15 – 75 psi

30 – 300 psi

Main valve and pilot valve

diaphragm and disc:

Buna-N® synthetic rubber

*The 90G-42 (globe) and

90A-42 (angle) in cast

steel are supplied with

standard internal and

external epoxy coating

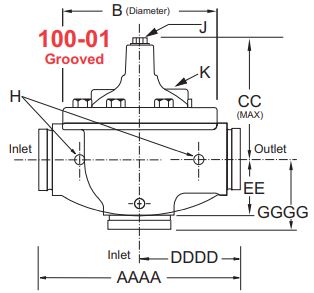

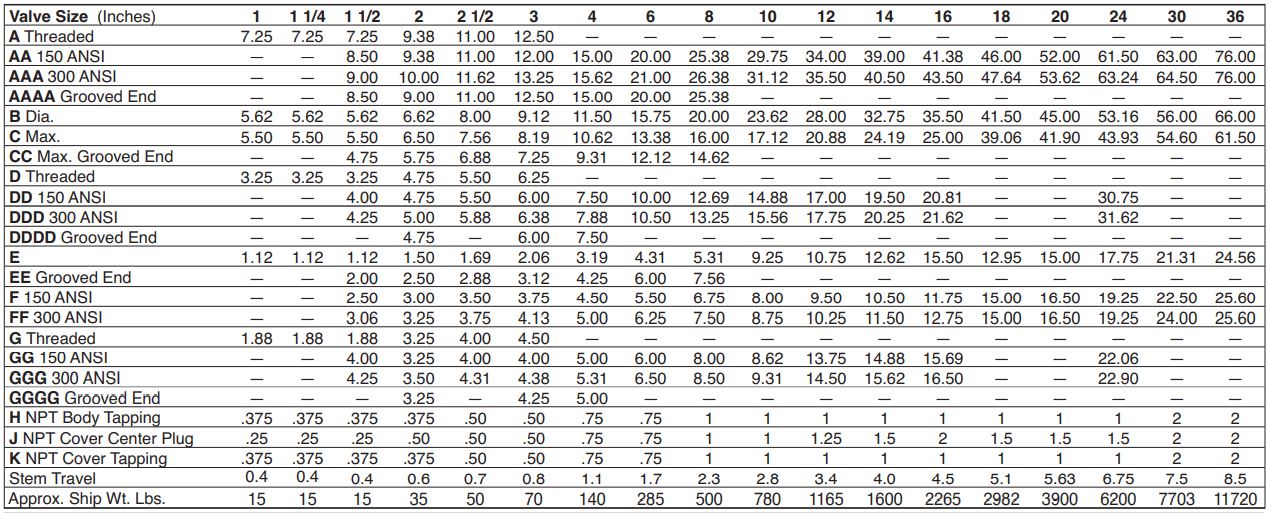

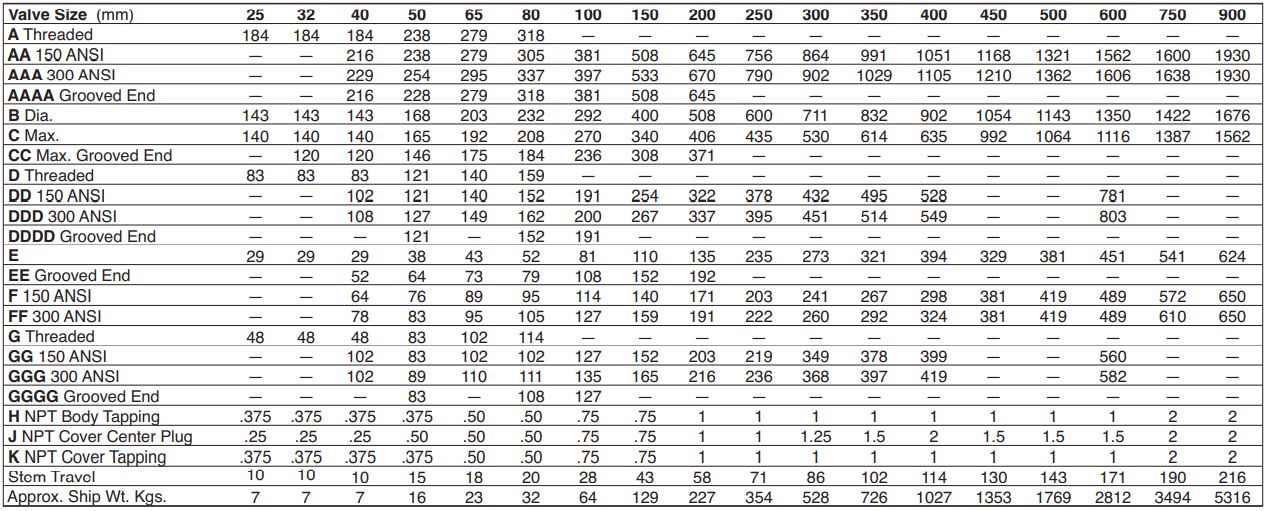

Model 90-42 Dimensions

When Ordering

Please Specify

1. Model No. 90-42

2. Size

3. Globe or Angle

4. Main Valve Body and Cover Material

5. Threaded, Flanged or Grooved

6. Pressure Class

7. Adjustment Range

Cla-Val Control Valves operate with maximum efficiency when mounted in horizontal piping with the main valve cover UP, however, other positions are acceptable. Due to component size and weight of 8 inch and larger valves, installation with cover UP is advisable. We recommend isolation valves be installed on inlet and outlet for maintenance. Adequate space above and around the valve for service personnel should be considered essential. A regular maintenance program should be established based on the specific application data. However, we recommend a thorough inspection be done at least once a year. Consult factory for specific recommendations.

*For UL Listed, see Cla-Val Model 90-21 for sizes and pressure class information.