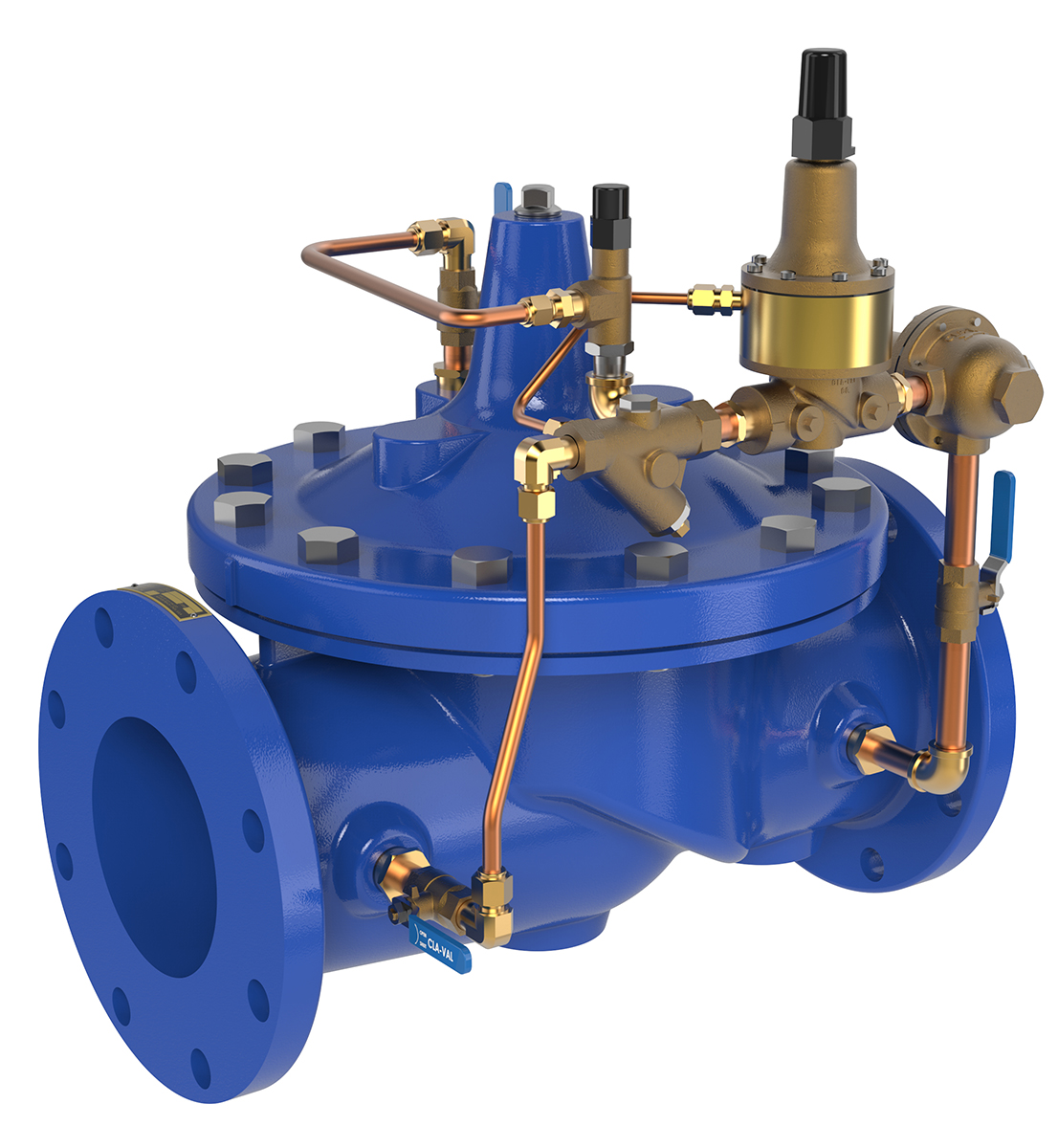

Combination Pressure Reducing & Pressure Sustaining Valve

Product Advantages

- Accurate Response to Slight Pressure Changes

- Check Feature Available

- Completely Automatic Operation

- Drip-Tight, Positive Seating Action

- Operation is Fully Hydraulic

The Cla-Val Model 92-01 Combination Pressure Reducing and Pressure Sustaining Valve automatically performs two independent functions. It maintains a constant downstream pressure, regardless of fluctuating demand and sustains the upstream pressure to a predetermined minimum.

The pressure reducing control responds to slight variations in downstream pressure and immediately repositions the main valve to maintain the desired downstream pressure. The pressure sustaining control is normally held open by the upstream pressure, but modulates should the pressure drop to the control set point. This, in turn, modulates the main valve to sustain the desired upstream pressure.

If a check feature is added, and a pressure reversal occurs, the downstream pressure is admitted into the main valve cover chamber and the valve closes to prevent return flow.

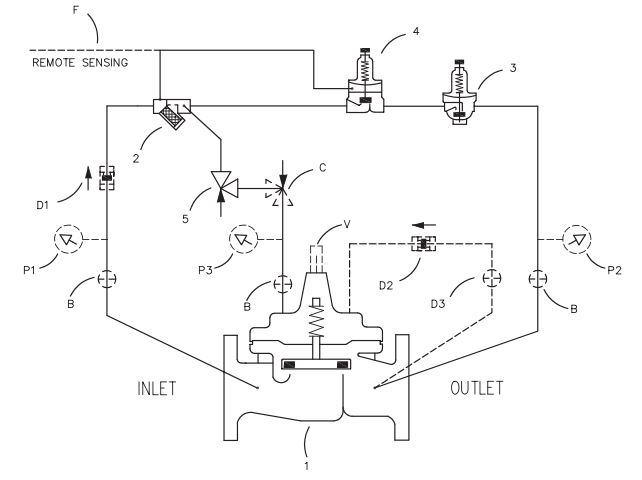

Schematic Diagram

Item Description

1. 100-01 Hytrol Main Valve

2. X44A Strainer & Orifice

3. CRD Pressure Reducing Control

4. CRL-60 Pressure Relief Control

5. CV Flow Control (Opening)

Optional Features

Item Description

B. CK2 Isolation Valve

C. CV Flow Control (Closing)*

D. Check Valves With Isolation Valve

F. Remote Pilot Sensing

P. X141 Pressure Gauge

V. X101 Valve Position Indicator

* The (optional) closing speed control on this valve should

always be open at least three (3) turns off its seat.

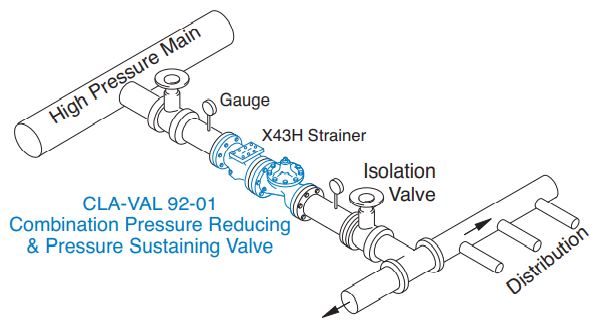

Typical Application

A Combination Pressure Reducing and Pressure Sustaining Valve is typically used to automatically reduce pressure for the downstream distribution network and sustain a minimum pressure in the high pressure main regardless of distribution demand.

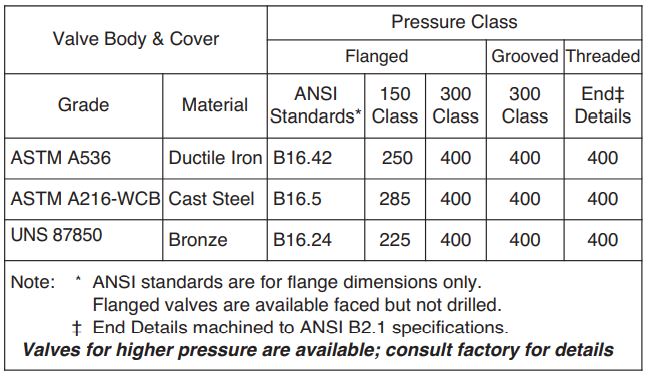

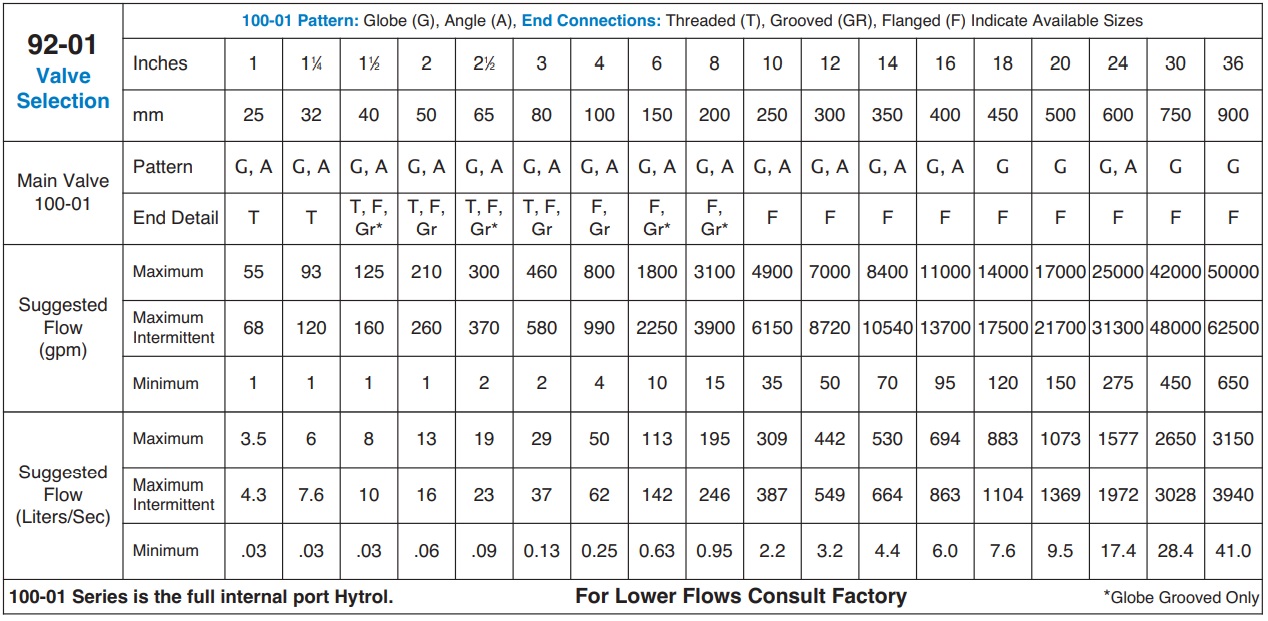

Model 92-01 (Uses 100-01 Hytrol Main Valve)

Pressure Ratings (Recommended Maximum Pressure – psi)

Materials

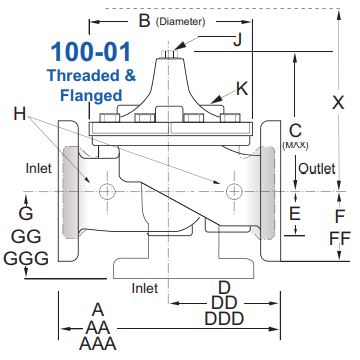

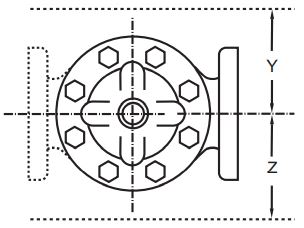

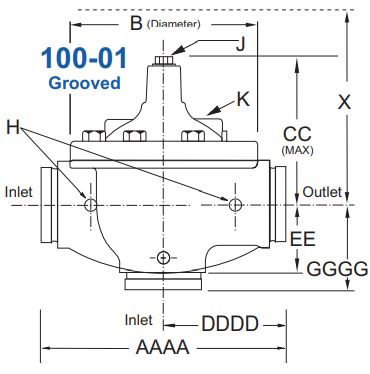

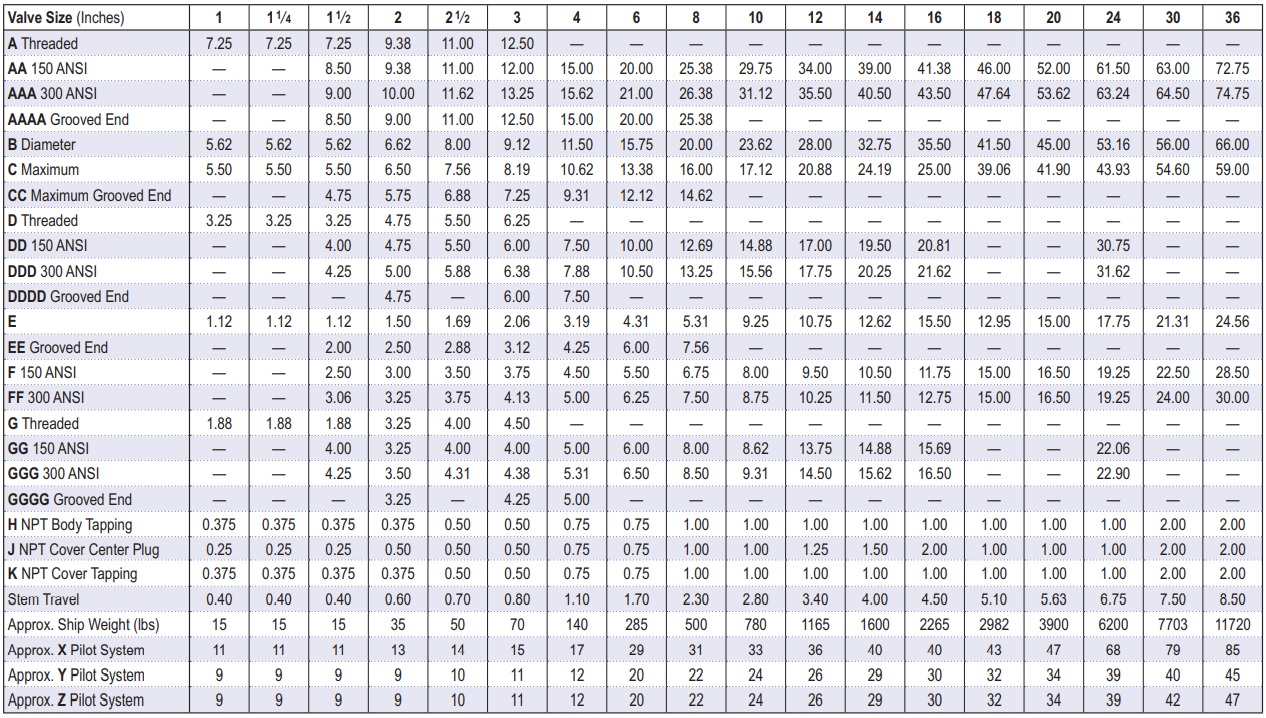

Model 92-01 Dimensions (In Inches)

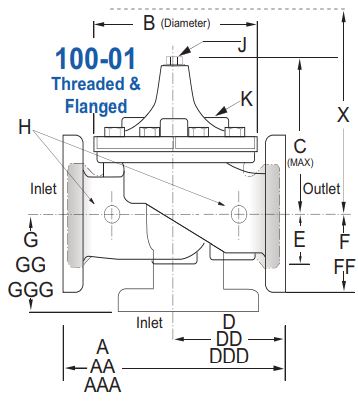

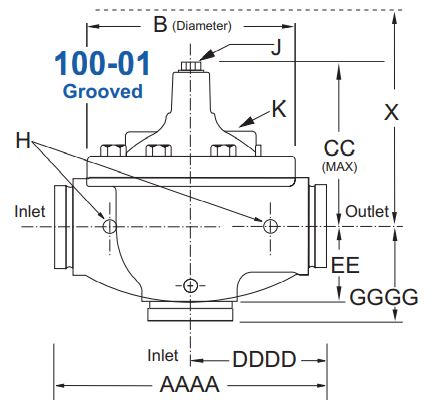

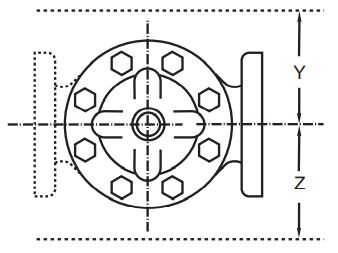

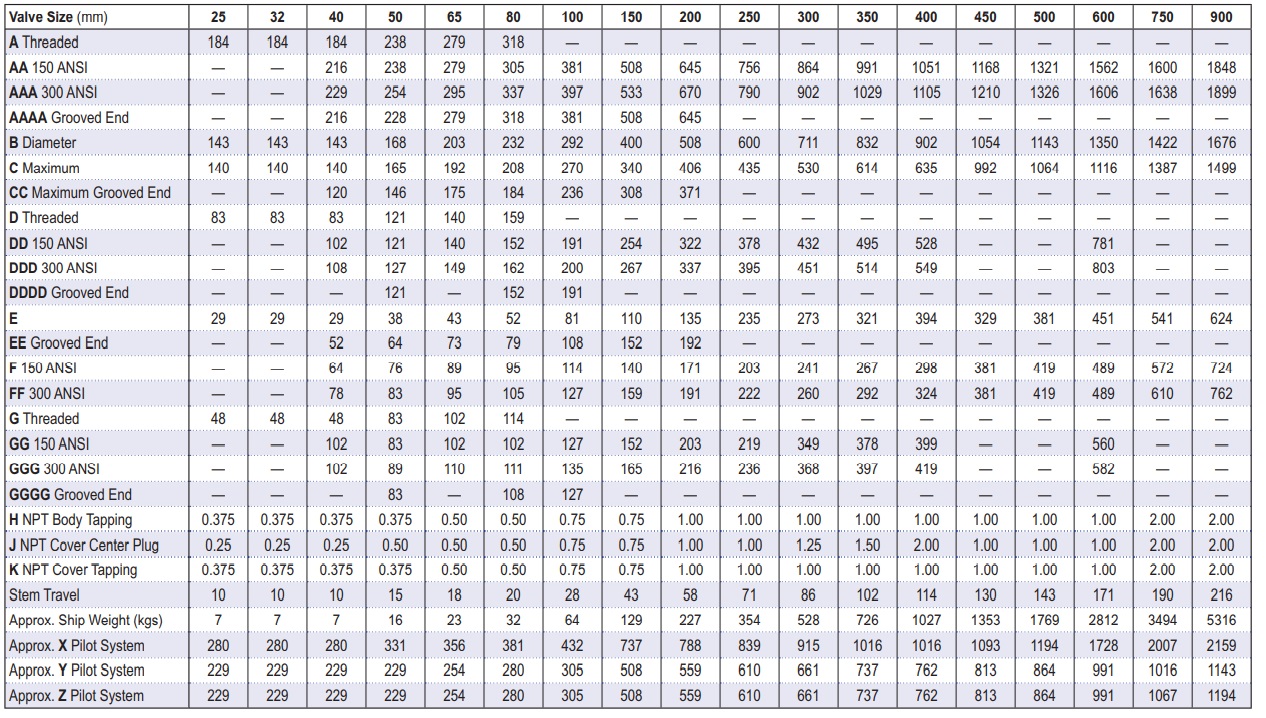

Model 92-01 Metric Dimensions (Uses the 100-01 Hytrol Main Valve)

Valve Options

X141 Pressure

Gauge

X101AR Valve

Position Indicator

with Air Release

X101

Valve Position

Indicator

X144 e-FlowMeter

X43H

Strainer

X43H

Strainer

Stainless

Steel Pilot

92-01 Dimensions (In mm)

CRD Pressure Reducing Pilot Control

The CRD Pilot is held open by the force of the compression spring above the diaphragm, and closes when the downstream pressure acting on the underside of the diaphragm exceeds the spring setting. The CRD senses downstream pressure directly.

Flow through the control responds to changes in downstream pressure. Turning the adjusting screw clockwise increases the delivery pressure. Turning it counterclockwise decreases the pressure. A resilient disc assures tight shut-off on dead-end service.

See the E-CRD E-Sheet for more details.

CRL-60 Pressure Relief Pilot Control

The Model CRL-60 is normally held closed by the force of the compression spring above the diaphragm. Control pressure is applied under the diaphragm. When the controlling pressure exceeds the spring setting, the disc is lifted off its seat, permitting flow through the control. When control pressure drops below the spring setting, the spring forces the control back to its normally closed position. The controlling pressure is applied to the chamber beneath the diaphragm through a sensing port on the CRL-60 body.

See the E-CRL-60 E-Sheet for more

details.

Pilot System Specifications

Adjustment Ranges

CRD

2 to 30 psi

15 to 75 psi

20 to 105 psi

30 to 300 psi*

CRL-60

0 to 75 psi

20 to 105 psi*

20 to 200 psi

100 to 300 psi

*Supplied unless otherwise specified

Other ranges available, please consult factory.

Materials

Standard Pilot System Materials

Pilot Control: Low Lead Bronze

Trim: Brass & Stainless Steel Type 303

Rubber: Buna-N® Synthetic Rubber

Optional Pilot System Materials

Pilot Systems are available with optional

Stainless Steel or Monel materials.

Note: Available with remote sensing control.

When Ordering,

Specify:

1. Catalog No. 92-01

2. Valve Size

3. Pattern – Globe or Angle

4. Pressure Class

5. Threaded or Flanged

6. Trim Material

7. Adjustment Range

8. Desired Options

9. When Vertically Installed