Electronic Valve Controller

Product Advantages

- Provides remote or local setpoint control for valves in a variety of fluid applications

- Highly accurate and stable valve control

- Controller is supplied with pre-loaded ValvApps™ for most common valve functions

- Custom ValvApps™ can be created for Multi Function Control

- Simple Control Curves graphical programming

- High resolution color screen graphics with color coded indicators

- Communications via standard 4-20 mA retransmission and relays or by Modbus RTU/TCP

- Internal logging : programmable and download to USB

- Less than 3 Watts power: solar or hydro powered remote valve control Simple and intuitive programming and set-up

- Option of: IP-65 NEMA Type 4 Housing Enclosure IP-68 Submersible (verified by independent lab) Panel Mount (fits 1/4 DIN or surface mount)

Product Description

The Cla-Val VC-22D is designed to provide state of the art valve control for a variety of fluid control parameters. Intuitive programming screens allow easy and fast programming for standard and customized applications such as flow, pressure, level, or position. Complete capabilities allow either stand-alone operation or easy integration into SCADA systems with standard wired signals or Modbus (TCP or RTU) communications.

For ease of use, the controller is pre-loaded with a wide variety of typical valve applications (ValvApps™). Additional custom ValvApps™ can be created by Cla-Val to meet any operational requirement. For example 2 or 3 modulating control functions can be combined into one custom ValveApp.

Pre-Loaded Typical ValvApps™ include:

• Flow Control with Mag Meter or e-Flowmeter Feedback

• Pressure Control with Upstream or Downstream Feedback

• Position Control with Position Feedback

• Modulating Level Control with Level and Position or Flow Feedback

• Metering Valve with Position and DP or P1-P2 Feedback

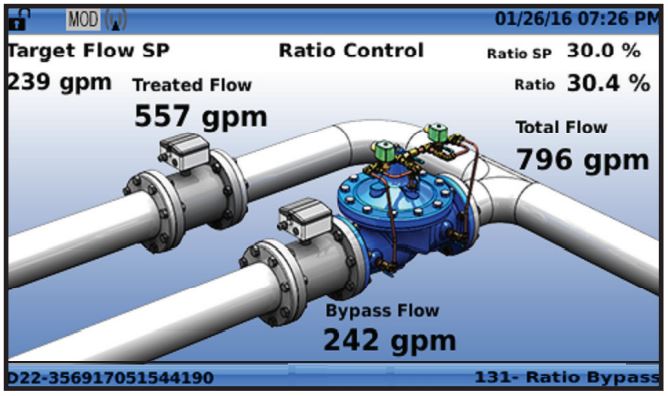

• Ratio Control with 2 Flowmeter feedbacks

• Altitude On/Off Level Control with Delayed Opening and Level Feedback

• Pressure Management with CRD-34 Electronic Pilots and Flow Feedback

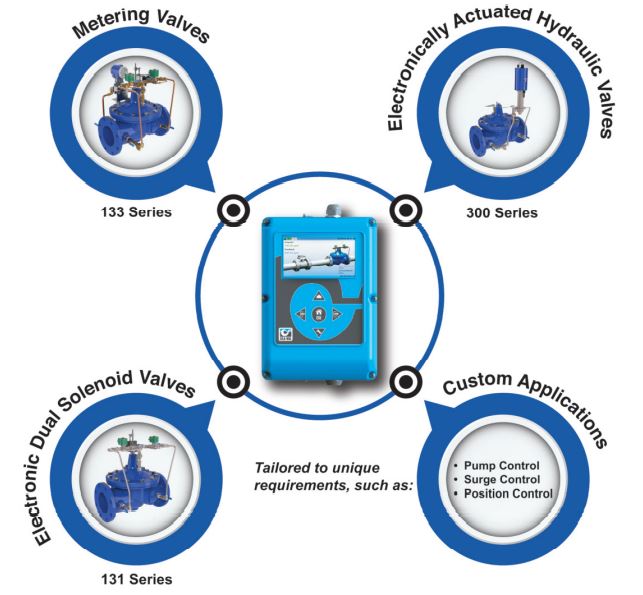

Controller Applications

VC-22D Valve Functions

PID Control

Used in maintaining a control valve at setpoint, multiple PID loops can be programmed with each of them offering local or remote setpoints. A real-time chart view helps to visualize valve response and fine tune valve response. Programmable setpoint ramping prevents hydraulic shocks.

Actions

Used to take “action” (or alarms) when programmable conditions (1 or 2) are met by forcing an output relay, solenoid, or 4-20 mA output. The closing relay can be used to send an alarm to SCADA. Up to four actions can be programmed including deadband.

Retransmission

Used to retransmit any input signal, variable, or calculation to a SCADA system. Up to four input signals such as pressure, flow, or level can be redirected through the 4-20 mA outputs.

DP Metering

A built-in function to calculate flowrate based on valve position and DP. The returned flow value can be displayed and controlled without a separate flow meter. A metering ValvApp with this feature is included in the standard internal library. All standard Cla-Val valve sizes curves are included.

Control Curves

Offers an easy way to create a relationship between two system variables. Using graphical functions, the user draws the control curve relationship linking pressure, flow, level, and/or time directly on the screen. Up to four control curves allowing independent pump control valve opening and closing or tailored modulating level control.

Totalizer

Keeps track of total volume as a function of time. Customizable units & reset functionality allow for simplified set-up and configuration. Can be used for volume (or batch) control applications limiting water volume taken from supplier per day or into tank trucks.

Data Logging and Log File

All input and output values are logged according to a programmable schedule. Default logging is every 5 minutes but can be as low as 1 minute or at customized intervals. 4 GB SD card memory allows greater than 80,000,000 values storage. Data is stored in MS-Excel (CSV) readable format. Transfer is by USB.

Enclosures

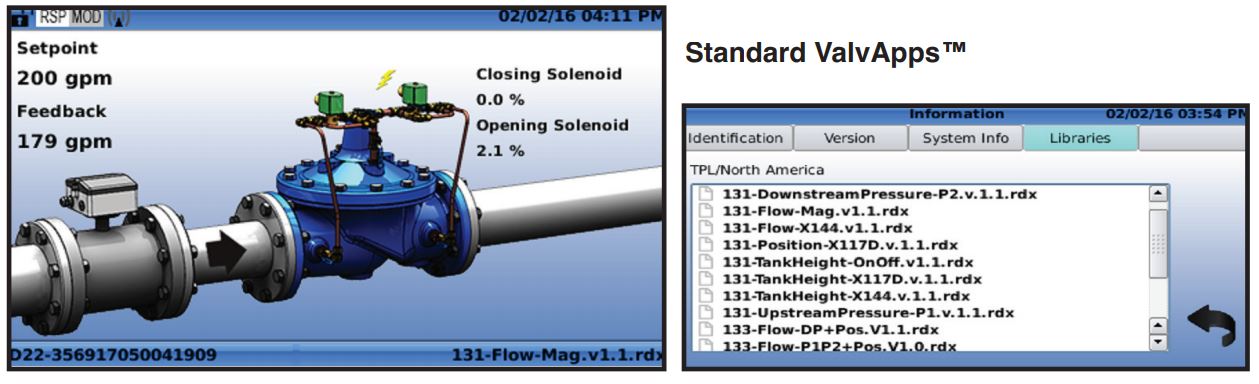

Standard & Custom ValvApps™

At startup the user can select from an internal library of Standard ValvApps designed for the most common control applications such as flow, pressure, level, position, or pressure management. Pre-configured graphics displays actual valve installation and minimizes startup time.

Custom ValvApps™

Special requirements can easily be handled by importing Custom ValvApps from the USB port. Program files may be either pre-programmed into the controller or sent by email and downloaded into the controller. All within minutes. Typical non-standard applications include ratio (blending), multiple functions, multiple inputs, custom graphics, differential pressure, temperature, salinity, electrical conductivity, parallel valves, etc.

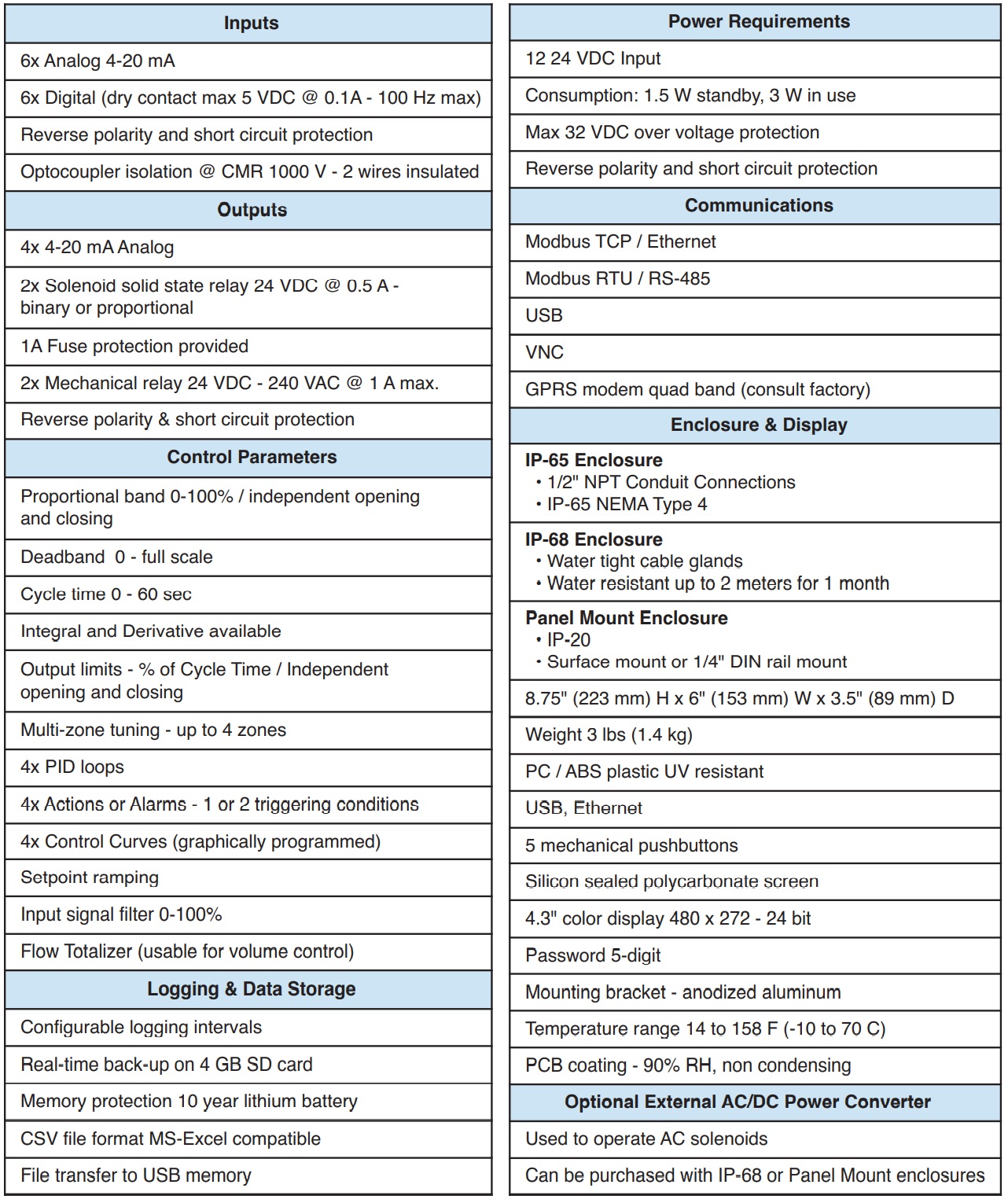

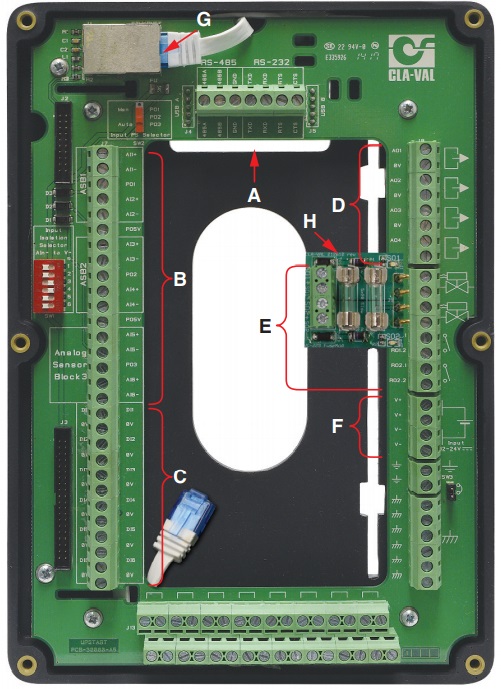

Inputs, Outputs & Communications

Features

A) RS-232/485

B) Six 4-20 mA Analog Inputs

C) Six Digital inputs

D) Four 4-20 mA Analog Outputs

E) Two Solenoid + Two Relay Outputs

F) 12 – 24 VDC Power

G) Ethernet Connection (External)

H) 1A Fuse Module

Typical installation with mounting bracket

VC-22D Valve Controller Product Specifications